GUANDIAO

The Oscillating Knife Cutting Machine is a device that utilizes high-speed vibrating blades to conduct cutting operations, allowing for precise and rapid execution of cuts across various materials. When compared to traditional cutting methods, the oscillating knife Cutting Machine boasts advantages such as heightened precision, increased speed, reduced energy consumption, and a broader processing range. This cutting technology is extensively employed in the processing of diverse materials such as leather, paper, plywood, plastic films, cork, foam, and corrugated paper, particularly excelling in the cutting of intricate patterns.

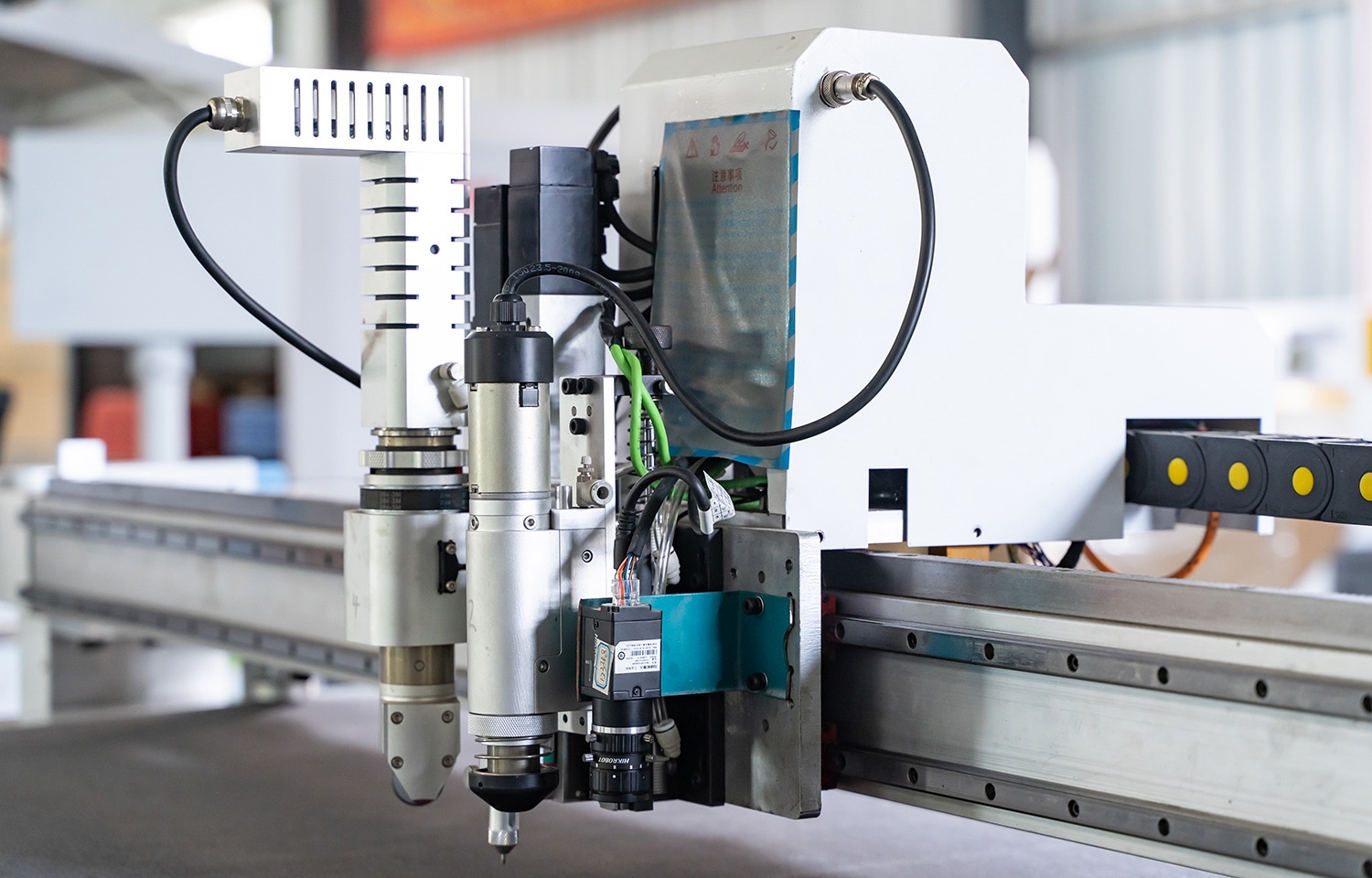

Fundamental Principle of the Oscillating Knife Cutting Machine

During operation, the oscillating knife Cutting Machine employs a control system to drive the blade in a high-frequency vibration mode to cut through materials. This high-frequency vibration significantly diminishes the frictional resistance between the blade and the material, thereby achieving a smooth and precise cutting outcome while minimizing material deformation and thermal effects during the cutting process.

Primary Applications of the Oscillating Knife Cutting Machine

Advertising Industry: Utilized for creating various signs, display boards, and three-dimensional letters.

Automotive Interiors: Cuts materials such as seat covers, carpets, and interior panels.

Packaging Industry: Used for cutting cardboard boxes and foam packaging materials.

Apparel/Textile Industry: Suitable for cutting various fabrics, leathers, and composite materials, particularly tailored for customized production demands.

Construction Industry: Employed in cutting decorative materials like wallpapers and flooring materials.

Electronics Industry: Cuts insulation materials and laminates.

Aerospace Industry: Used for cutting lightweight and composite materials.

Advantages of the Oscillating Knife Cutting Machine

High Precision and Flexibility: Capable of precisely following predefined paths to accommodate intricate pattern processing with ease.

Mold-Free Operation: Eliminates the need for traditional cutting molds, making it economical for small-scale or customized production.

Versatile Material Compatibility: Capable of handling a wide array of materials, including both soft and certain hard materials.

Enhanced Processing Efficiency: Offers higher processing efficiency compared to traditional manual or low-speed cutting.

Ease of Use: Often comes with user-friendly software systems that are easy to learn and operate.

Conclusion

With its flexibility, efficiency, and broad application spectrum, the oscillating knife Cutting Machine has become an indispensable tool in modern manufacturing processes. As technology continues to advance and innovate, the future applications of the oscillating knife Cutting Machine are expected to expand even further, meeting the demands for customization and high-efficiency production across various industries.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb