GUANDIAO

The plastic foam moulds process center is a kind of equipment specially designed for engraving and cutting styrofoam (EPS, i.e. expanded polystyrene) materials. Its working principle and application are similar to those of the foam engraving machine. Polylon is a lightweight, foam like plastic material. Because of its portability, good insulation, low cost and other characteristics, it is widely used in packaging, architecture, decoration, model making and other aspects.

The plastic foam moulds process center mainly works through two technologies:

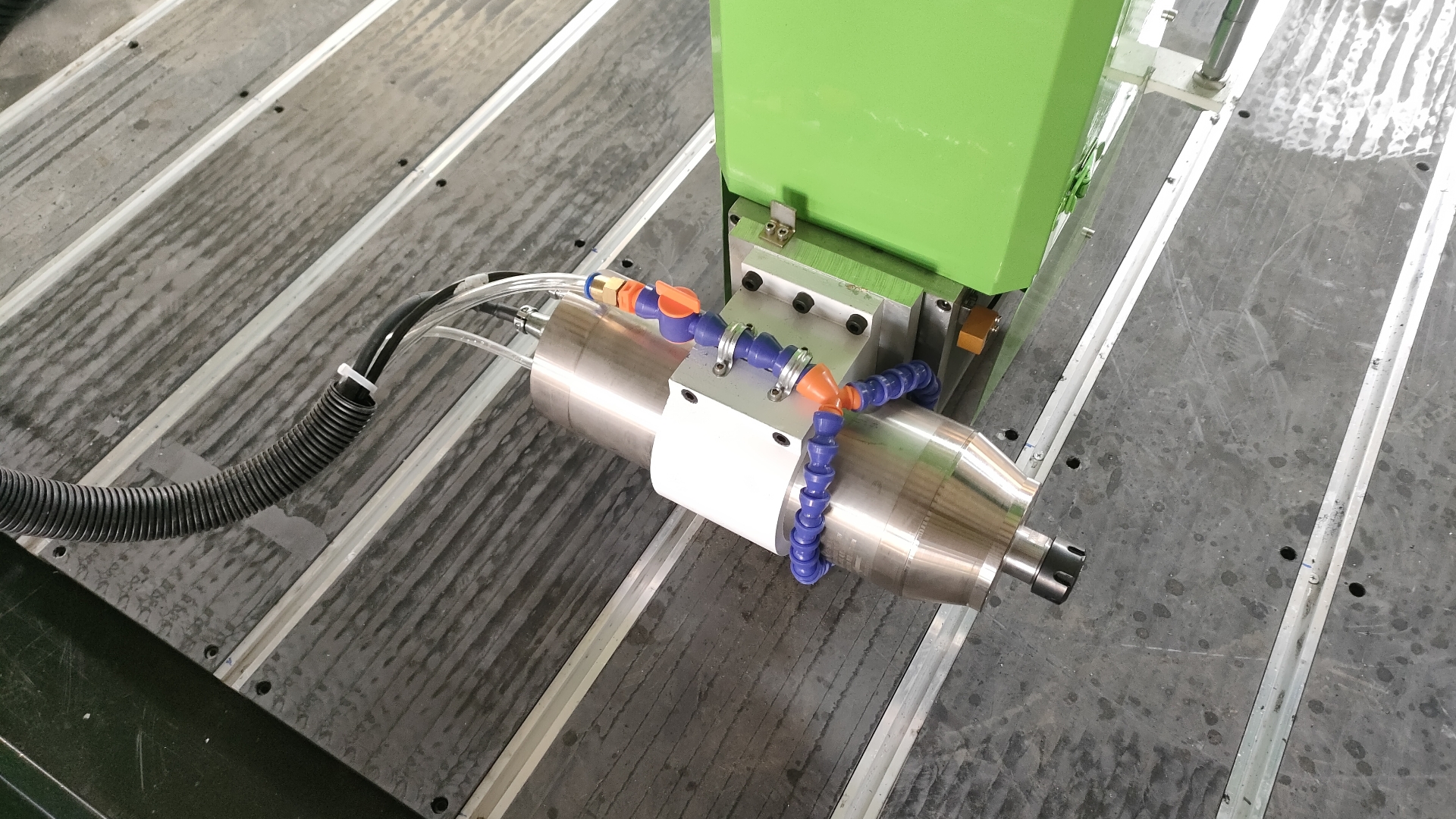

Mechanical carving: Using rotating cutting tools (such as carving cutters, milling cutters, etc.) to physically cut or carve Polylon materials, complex patterns and structures can be achieved. This type of plastic foam moulds process center can be equipped with CNC technology, which can achieve precise and complex engraving effects through computer programming control.

Hot cutting and carving: Using a heating wire (hot wire) to melt and cut polystyrene material. The thermal cutting method is suitable for cutting straight or curved lines, which can achieve smooth cutting edges and produce less debris during the cutting process. Hot cutting is suitable for decoration, art production, and the processing of some simple geometric shapes.

The sinking table and swinging head of the engraving machine are two important features that enhance its functionality and processing ability, each of which brings a series of advantages:

Sinking countertop

Suitable for large workpiece processing: The sinking table allows the engraving machine to adapt to larger workpieces, especially in terms of height. This is very useful for processing large sculptures, decorations, or building models with higher dimensions.

Stability enhancement: The sinking design of the countertop can bring the workpiece closer to the bottom of the machine tool, thereby increasing the stability of the workpiece, reducing vibration during the machining process, and improving machining accuracy.

Easy to operate: For some heavy or large workpieces, the sinking table can reduce the labor intensity during workpiece loading and unloading, which helps to improve the convenience of operation and work efficiency.

Swinging head (also known as shaft or rotation axis)

Multi angle machining: The swinging head allows the engraving machine to process at multiple angles, which means more complex 3D carving can be achieved, such as carving cylindrical or spherical objects, greatly expanding the machining range of the engraving machine.

Improving accuracy: By precisely controlling the swinging head, very complex design requirements can be achieved, improving the processing accuracy and detail expression of the product.

High efficiency: For workpieces that require multi sided machining, the swinging head can complete multi sided machining tasks without the need for manual flipping of the workpiece, saving time and improving production efficiency.

Creative flexibility: The use of swinging heads greatly increases the flexibility of design and creation, allowing designers to achieve more dynamic and three-dimensional creative ideas, enhancing the artistic effect and market competitiveness of their works.

Overall, the addition of sunken countertops and swinging heads significantly improves the applicability, processing capacity, and efficiency of carving machines, enabling them to meet a wider range of material, shape, and design needs. They have important application value in both industrial production and artistic creation fields.

The plastic foam moulds process center is relatively simple to operate, and precise machining of complex designs can be easily achieved through modern CNC technology. Whether in the fields of advertising production, scene layout, building models, packaging materials, or artistic creation, you can see the figure of the Polylong carving machine. It has become an indispensable processing tool in many industries due to its high efficiency, low cost, and versatility.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb