Machine working video:

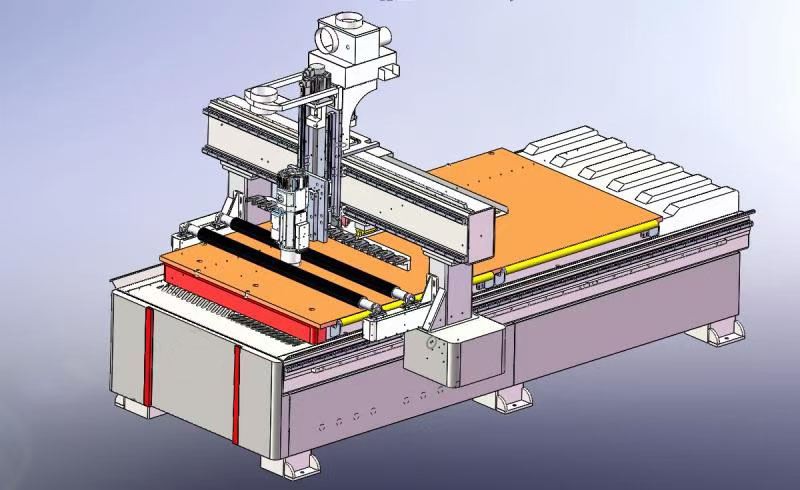

Machine Pictures:

1. It is mainly used for engraving and cutting on the wood plate and round shape. Especially for wood furniture factory,the machine will be a good assistant.

2. High-speed machining: the curve and straight speed is the same, the idle speed can reach 80m/min, the cutting speed can reach 30m/min.

3. The weight loading and redundancy are high, the working life is long: three axes adopt the imported line square guide rail with the high precision, Axis Y adopts the double engine driving, the rigidity of machine is strong, the potency dimension is powerful, the turn is balanced.

4. Compatiility of software: it may be compatible with all kinds of software

Machine Details:

#High Quality big power ATC spindle with ATC tools magazine

#High quality big power motors and drivers to ensure machine can be work more stable

#Famous Brand Delta Control system

#Independent electrical box with high quality control system and handle wheel

#Air fan can protect the electrical components from high temperature

#Air conditioner for optional

#Auto lubrication system

#Ensure machine can be working smooth then to protect guide rail and rack

#Loading wheels to avoid panel sratch and help workers to loading materials more easily

#Humanization design for workers

Machine Parameters:

| Model | GD-1325A/GD-1325B |

| Working area | 1300*2500mm |

| Table size | 1740*3100mm |

| Z-axis working area | 200-300mm(optional) |

| Resolution | +/- 0.01mm |

| Max Cutting Speed | 70m/min |

| X and Y axis transmission | Germany Herion 1.5MRack and Pinion |

| Z-axis transmission | Germany TBI Ball Screw |

| Guide rail | Taiwan Hiwin 25mm Linear rail |

| Spindle | 9.0KW, air-cooling |

| Working Mode | Japan yaskawa 750W Servo motor |

| XY Transmission | Imported Rack |

| Z transmission | Taiwan TBI Ball screw |

| Reudcer | Japan Shimpo |

2. Besides the spindle, we use high quality components on this machine like servo motors and servo drivers

3. The whole machine adopts seamless welding of steel structure, with strong bearing capacity and small deformation. Linear square rail, high precision, wear resistance and stable operation.

4. Adopt linear, disc or follow-type automatic tool change system, the tool change time only needs ten seconds, which saves tool change time and improves production efficiency.

5. It has the function of breakpoint and continuous engraving after power failure, and automatic error correction function when returning to the origin, which effectively guarantees the processing accuracy when working for a long time.

Machine Application:

wood door and furniture decoration industry

solid wood compound door, cabinet door, large area plate plane carving, solid wood carving, board furniture carving, antique mahogany furniture carving, solid wood art fresco carving and other industries.

wooden handicraft processing clock frame, process photo frame, calligraphy card, electrical counter Surface, sports equipment, thin aluminum plate carving.

Mold: wood,wax, wood, foams.

Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

The wood products: voice box, game cabinets, computer tables, sewing machines table,instruments.

Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate

board, epoxy resin, ABS, PP, PE. 5) Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals: such as copper, aluminum plate engraving and milling process.

About us:

Shandong Guandiao CNC Equipment Co., Ltd is an innovative enterprise engaged in research and development,production, sales and good after- sales service. The company’s main products include Panel furniture CNC cutting machine, Woodworking CNC Machining Center, CNC router , Multi-head cylinder CNC engraving machine, Styrofoam CNC router, 3D scanner, Vacuum membrane press machine, Vacuum forming machine, Laser engraving and cutting machine, etc.

FAQ

Q: How to install and maintain the machine?

A: Before you use it, we will send the operation tutorial and installation operation video with English version to you. If you still can not operate, we will provide video guidance online.

Q: What are the machine working environment requirements?

A: The machine should be fixed on a environment should be kept clean and tidy to avoid contact with dust,static electricity, humidity, and chips to cause parts failure.

Q: What about after-sales service? How long is the warranty period?

A: We offer 24 hours online video call to solve your problems. We have a standby team ready to assist you at any given time. Machine maintenance requirement will be provided to you upon purchase. On all machinery we offer 1 year warranty and 6 months warranty for core components.

Contact Information:

Hot Tags: 2040 atc woodworking cnc, China, suppliers, manufacturers, factory, price, wholesale, for sale, Woodworking CNC Machine, Woodworking CNC Router, ATC CNC Wood Router Machine, CNC Woodworking Router Machine, Mini CNC Router, Wood Cutting Machine