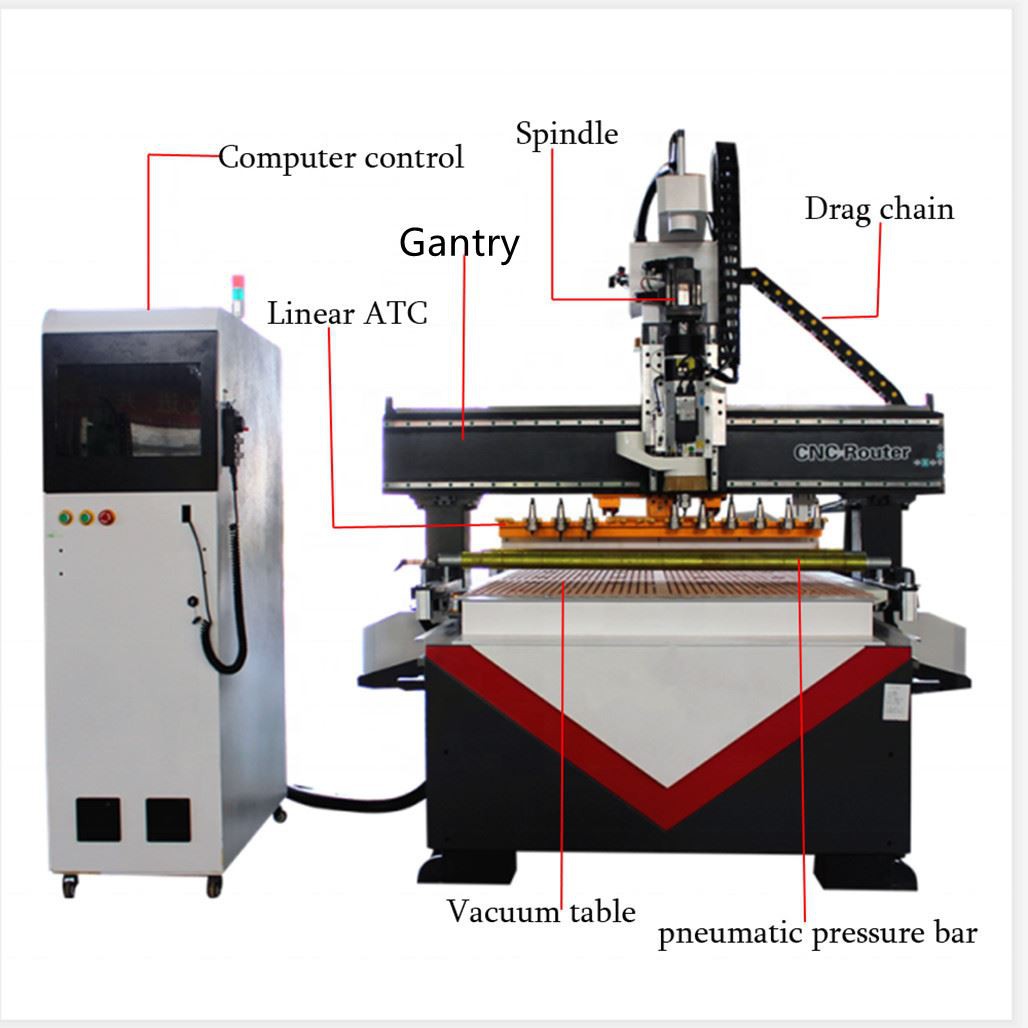

ATC 5 axis woodworking machinery

Features:

1. Machine body design with high strength and double driving motors of Y axis, which have more

reasonable design, fast processing speed, easy-operated maintenance and low fault rate.

2. Advanced CNC processing system has powerful functions and humanized operation, as well as can

receive data through U disk or network.

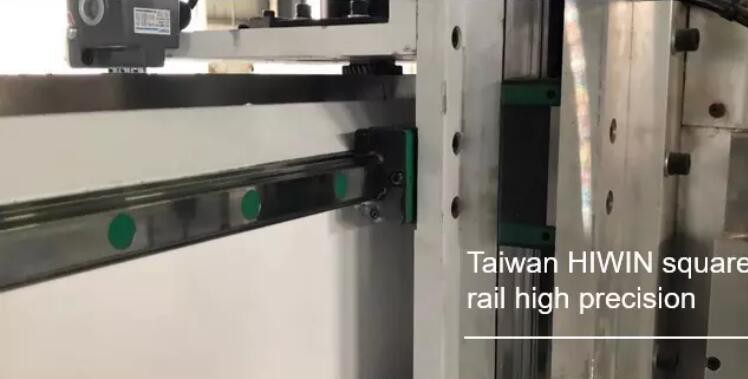

3. Imported and high precise linear guide ways have features such as stable operation, high precision

and steady support, which prolong service life of machines.

4. Z axis adopts imported ball screw with industrial level can positioning accurately and make processing effects more perfect.

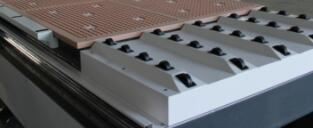

5. Energy-saving vacuum absorption table function and dust collectors can protect the environment.

6. Software has good compatibility. The machine can be compatible with various CAD/CAM design &

making software such as TYPE3, Artcam, JD, Artcut, UG, MasterCAM, PowerMill and so on.

Machine parameters

Mode | 1325 atc woodworking cnc machine | |

1 | Working size | 1300*2500*200mm (size can be customized) |

2 | Spindle speed | Max working speed: 18000-24000rpm |

3 | Machine body | 12mm steel structure welding, big gantry |

4 | Spindle | HSD 9.0KW ATC spindle (hqd optional) |

5 | Drive | Taiwan Dorna Servo motor |

6 | Z axis | 1.2 kw servo motor with emergence stop system |

7 | Reducer | Shimpo reducer |

8 | Gear rack | XY axis: Taiwan rack Z axis: TBL ball screw |

9 | Guide rail | Taiwan Hinwin 25mm square guide rail |

10 | Cylinder | Taiwan Airtac special cylinder |

11 | Electromagnetic Valve | Taiwan Airtac electromagnetic valve |

12 | Electrical element | France imported Schneider |

13 | Table | Vacuum+T-slot with 6 zones |

14 | Material positioning | L mode square 3+2 positioning cylinder |

15 | Control system | Taiwan LNC control system with guide handwheel |

16 | Lubrication system | automatic |

17 | Wire cable | Shanghai Yichu wire cable |

18 | Inverter | Hpmont 11kw |

19 | Loading and uploading | With auxiliary loading roller and auto unloading device |

Detail Images

|

|

|

|

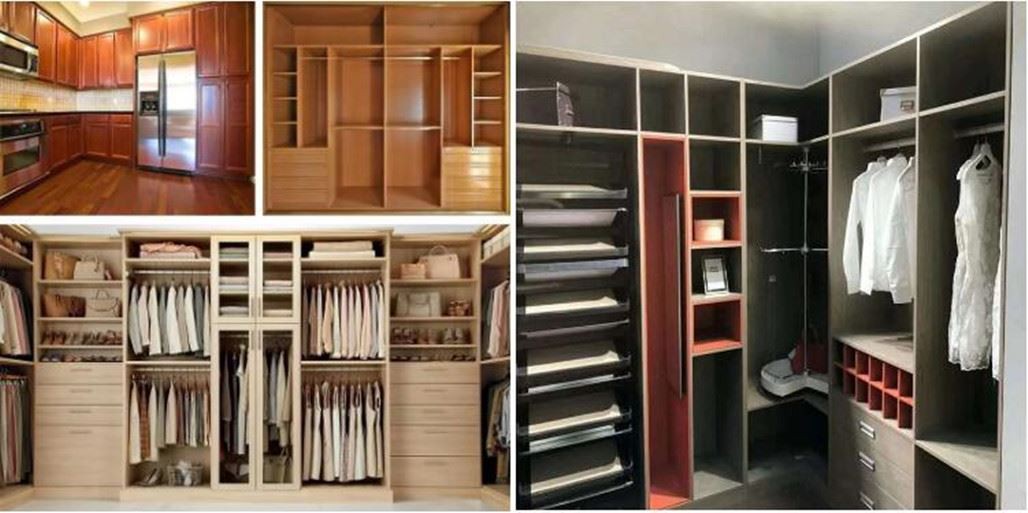

Machine Working Application

Woodworking: processing of various furniture such as door, window, cabinet, craft wood door, screen,etc

Advertisement: engraving and cutting various labels and number plate.

Art craft: engraving characters of any languages and graphics on gifts and souvenirs.

Balustrade,furniture legs,stair railing ,cylinder items,handrail,desk or chair legs,teatray,The human body,avatar,3D cylinder mold,and a variety of rotational symmetry.

Applicable materials:Wood, aluminum board, plastic, density board, wave board, PVC, acrylic,crystal, light marble and other nonmetal materials and light metal materials.

Company profile

|

|

Packing&Shipping

1) Whole film packaging machine.

2) Anti-collision package edge. 3) Fumigation-free plywood wooden box with an iron-binding belt. 4) According to the customer's requirements for loading the whole container or LCL at Qingdao Port.

FAQ

1. How to use the machine after receving the machine

Firstly , when you got machine , you need to contact with us ,our engineerwill together with your to deal with it ,secondly ,wesend user manuals and CD to you before you get the machine ,Thirdly Ourprofessional technician online teach you until you can use it well by yourself.

2.Payment termsThere are 2 ways to pay money .

1)T/T, means international bank transfer. 30% deposit, we produce the machine for you. 70% before shipping.It is convenient and fast.

2)Alibaba Secure payment. Reliable and safe, Alibaba will charge a little handling fee.

3.How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience. Other kinds of payment we can consider if acceptable for us.

Hot Tags: atc 5 axis woodworking machinery, China, suppliers, manufacturers, factory, price, wholesale, for sale, Wood Cutting Machine, Woodworking CNC Router, CNC Woodworking Router Machine, ATC CNC Wood Router Machine, Mini CNC Router, Woodworking CNC Machine