Machine Working video:

Machine Specifications:

1. Perfect Function, Automatic feeding, cutting and optimization, playing vertical hole, automatic cutting coherent, continuous processes, automatic unloading in one step, maximize efficiency output

2. Saving time and labor,materials,Automatic layout optimization,improve material utilization.High quantity,automatic design,automatic typesetting,no human intervention, minimizing error rate to minimum,ensure the quality of the order.

3. High efficiency, advanced disc automatic tool change program,without human intervention,program automatically.

4. Strong adsorption capacity, 7.5kw vacuum pump, vacuum table with 1325 vacuum holes, to suck tightly of the work piece,24 partition design,strong adsorption materials of different area,greatly improve the work efficiency.

5. The position sensor and Positioning cylinder satisfy the requirement of the high precision orientation, highly automating production lines.

#Imported Italian 9KW HSD ATC Spindle and HSD drilling head

#High Quality,Quick release,High power and High speed

#Linear tools magazine with 12 tools,you can choose the tools quantity

#Pressure roller to fix your materials more tightly on table when working

#Famous brand Taiwan Syntec control system

#Easy operate and Friendly for new customer

#The up-loading table has an automatic induction photoelectric switch

#Can automatically rise and fall. It can keep the height of the sheet consistent with the processing table.

#Some signal on the unloading table

#It can know if the panel on the under then to move it

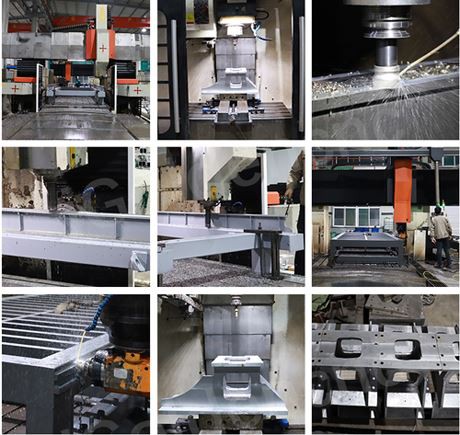

The machine body will be working by big 5 axis milling machine to ensure high presicion

Machine Parameters:

| Model | GD-1325A/GD-1325B |

| XY working area | 1300*2500mm(working area can be customized according to your needs) |

| Z axis | 200mm-300mm(option) |

| Max Cutting Speed | 70m/min |

| Transmission system | XY axis: Germany Herion 1.5MRack and Pinion Z: Germany TBI Ball Screw |

| Guide rail | Taiwan Hiwin 25mm Linear rail |

| Working Table | T slot Vacuum table 6 And T clamp combination |

| Spindle | 9.0kw ATC air cooling spindle |

| Control system | Taiwan Syntec control system |

| Drive system | 1.5kw servo motor and driver |

| Air pump | 7.5KW |

| Dust collector | 4KW,double bags |

| Inverter | HPMANT 11KW |

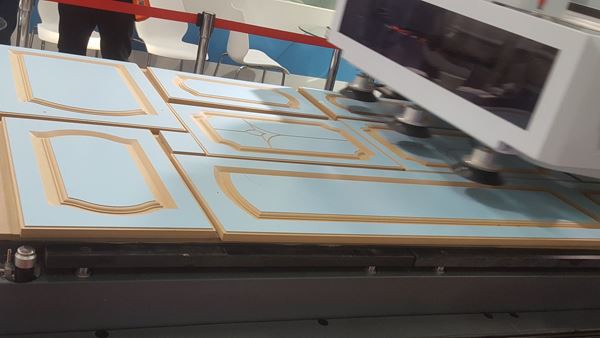

Machine samples:

About us:

FAQ

Q1: How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine

according to our experience.

Q2: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can also help you by "Team

viewer"online, with telephone or Skype explain.

Q3: Can you customize the machine for me?

Yes, we provide customized solution, but considering the cost, we will recommend the standard configuration to you first.

Q4: What is the guarantee? In case the machine break down?

The machine has 1 year guarantee, fail parts will be replaced for free if the machine under "normal operation".

Contact information:

Hot Tags: auto nesting atc cnc router for furniture cabinet, China, suppliers, manufacturers, factory, price, wholesale, for sale, ATC CNC Wood Router Machine, Woodworking CNC Machine, Mini CNC Router, Woodworking CNC Router, CNC Woodworking Router Machine, Wood Cutting Machine