Machine working video:

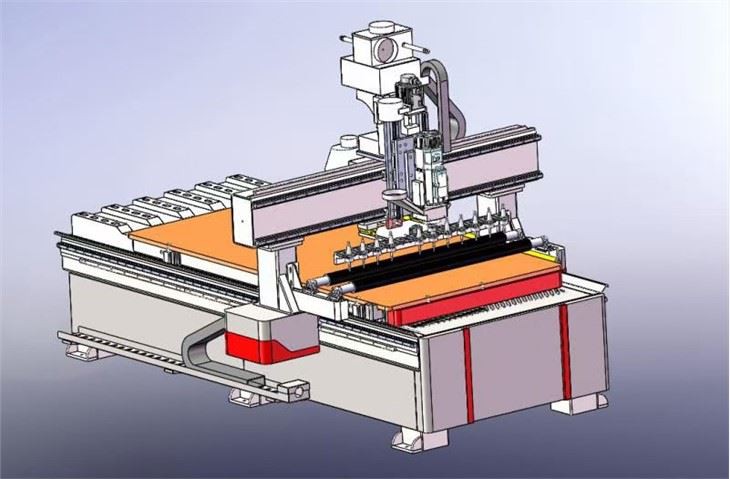

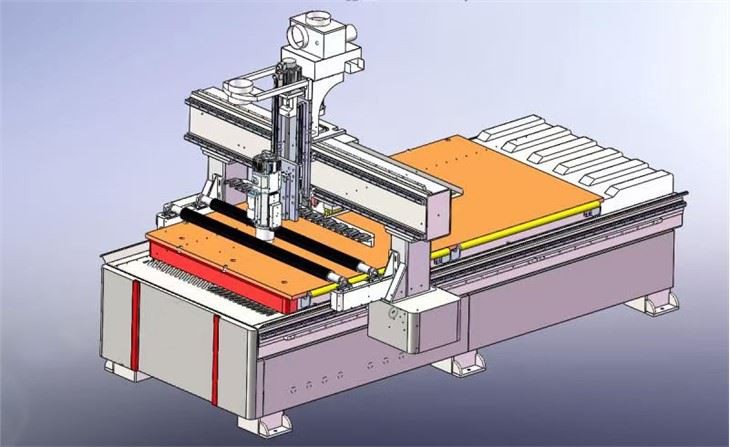

Machine Pictures:

Machine Details:

Automatic tool change spindle

High-precision automatic tool change spindle, fast tool change speed, no heat, can be installed with a variety of chucks,

can quickly complete three-in-one hole, two-in-one hole, hinge hole. Maintenance is simple.

Rack

High-precision imported wedge-shaped rack Heavy-duty bed Finished finish Large specifications,

large contact surface, strong load carrying capacity, better stability during high-speed machining.

Vacuum working Table

Vacuum 6 zone adsorption table surface is delicate and uniform,

it is perfect to solve the running board problem with 7.5KW vacuum pump.

Big Touch Screen.

Mouse and keyboard operation Convenient and easy to learn High precision High stability.

The operator can be employed with simple training without technicians. The machine moves quickly and efficiently.

Machine Parameters:

| Model | GD-1325A/GD-1325B |

| Working area | 1300*2500mm |

| Table size | 1740*3100mm |

| Z-axis working area | 200-300mm(optional) |

| Resolution | +/- 0.01mm |

| Max Cutting Speed | 70m/min |

| X and Y axis transmission | Germany Herion 1.5MRack and Pinion |

| Z-axis transmission | Germany TBI Ball Screw |

| Guide rail | Taiwan Hiwin 25mm Linear rail |

| Spindle | 9.0KW, air-cooling |

| Working Mode | Japan yaskawa 750W Servo motor |

| XY Transmission | Imported Rack |

| Z transmission | Taiwan TBI Ball screw |

| Reudcer |

Japan Shimpo |

Machine Application:

Woodworking: processing of various furniture such as door, window, cabinet, craft wood door, screen,etc

Advertisement: engraving and cutting various labels and number plate.

Art craft: engraving characters of any languages and graphics on gifts and souvenirs.

Balustrade,furniture legs,stair railing ,cylinder items,handrail,desk or chair legs,teatray,The human body,avatar,3D cylinder mold,and a variety of rotational symmetry.

Applicable materials:Wood, aluminum board, plastic, density board, wave board, PVC, acrylic,crystal, light marble and other nonmetal materials and light metal materials.

About us:

Frequency Asked Question

Q1: How do I get the best price?

A: As you may know,the different type of CNC machine apply to the different pricre.

Q2: What machine suits me best?

A: Different material and the different model apply to the different machine.

Please tell us what’s material you want to cutting or engraving ?

And what’s MAX size of carved material ?

Then we will recommand the most suitable model and the best price for you.

Q3: In case of failure,how to do?

A: Call us----our enginners are online for 24-hours,and ready to serve you.

Replacement of damaged parts for free---For more information,please contact us

The CD and operation manual----It show the most common failure in working processing and how to solve this problems.

Q4: Are you trading company or manufacturer ?

A: We are factory.

Q5: How long is your delivery time?

A: Generally it is a week days if the goods are in stock. or it is 15 working days if the goods are not in stock, it is according to quantity.

Our Service

Pre-Sales Service

1.We have many exhibitions very year, hundreds of clients was coming to our booth for further communication.2. 24-hours online Inquiry and consulting support.

3.Support sample testing .

4.We welcome you to visit our factory.

1. Training how to instal the machine, training how to use the machine online.

2. Engineers available to clients' factory for training.

3.Guarantee for one year

4.24-hour technical support by email or calling

5.User-friendly English manual for machine using and maintaining

6.Free technician training for customers.

We know for enterprises, quality is the life, so we have put the quality control into each link as products development, design, purchasing, processing, assembling and testing etc. Everybody in the company are participated into the quality management to prevent any unqualified products from being sent out before delivery, each machine has been inspected through following steps:

1.100% quality testing, that is, each machine has been tested strictly in mechanical assembling and electrical performing before delivery;

2.100% sample testing, that is, each machine has been tested by the processed sample before delivery;

3.We always pursue the service philosophy of "ALL FOR CUSTOMERS". The Advanced management system and perfect service

system ensure that we can provide timely and efficient services and ensure product's stability in great extent, which supply a effective guarantee for the system normal operation.

Contact Information:

Hot Tags: woodworking cnc atc center router, China, suppliers, manufacturers, factory, price, wholesale, for sale, Woodworking CNC Machine, Woodworking CNC Router, Wood Cutting Machine, ATC CNC Wood Router Machine, Mini CNC Router, CNC Woodworking Router Machine