GUANDIAO

Edge Banding Machine Specification:

Model | GD-2400 Automatic Edge Banding Machine |

Panel Feed Speed(m/min) | 15m/min |

Edge Thickness | 0.4-3mm |

Edge Width | 10-50mm |

Edge banding height | 12-60mm |

Panel thickness | 8-30mm |

Mini work Panel Width | > 80mm |

Mini work Panel Length | >120 Mm |

Heating power of plastic box | 1.5kw |

Plate preheating power | 0.37KW |

End cutting motor power | 0.55kw * 2 1200r / min200HZ |

Transmission motor power | 2.2KW |

Polishing motor power | 0.18kw*2 1400r / min 300Hz |

Fine trimming motor power | 0.75kw*2 1800r / min 300Hz |

Total power | 10kw |

Air pressure | 0.9MPA |

Machine weight | 2200KG |

Machine size | 4500*900*1500mm |

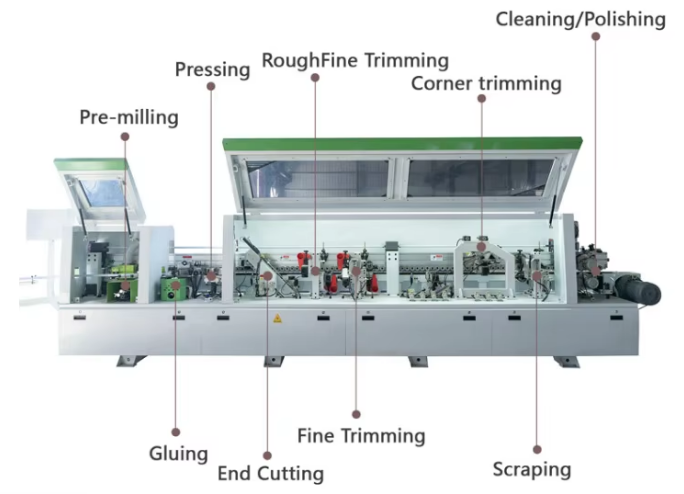

Edge Banding Machine with 6 basic functions

Gluing Traditional way of gluing is stable, Teflon coated glue pot for EVA hot-melt glue has a high capacity.(about 5L)

Front and end cutting Linear guide way structure at an angle of 45 degrees with 2 motors (0.35kw 200hz 12000rmp/min) to remove the extra edge tape on front and back.

Double trimming

Rough trimming unit with 2

powerful motors(power 0.75kw;

frequency 200hz; rotating speed

1,2000 rpm/min )and 2 milling

cutters; Fine trimming, 2 motors (power:

0.55kw; frequency:200hz, rotating

speed:12000rpm/min).

Scrapping Scraping the edge by R2 cutters(Standard), making edge banding more beautiful. Air blowing device blowing toward the scraping. cutters on upside and underside for cleaning the scraps on cutter surface and cooling.

BUFFING

Buffing by dual screen cloth structure is the last step to make perfect edge banding to make the edge shining, more stable.

2 optional functions

Corner rounding Cut the four corners of the edging into arcs.

Pre-milling Cut the burrs off the planks before edge banding.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb