GUANDIAO

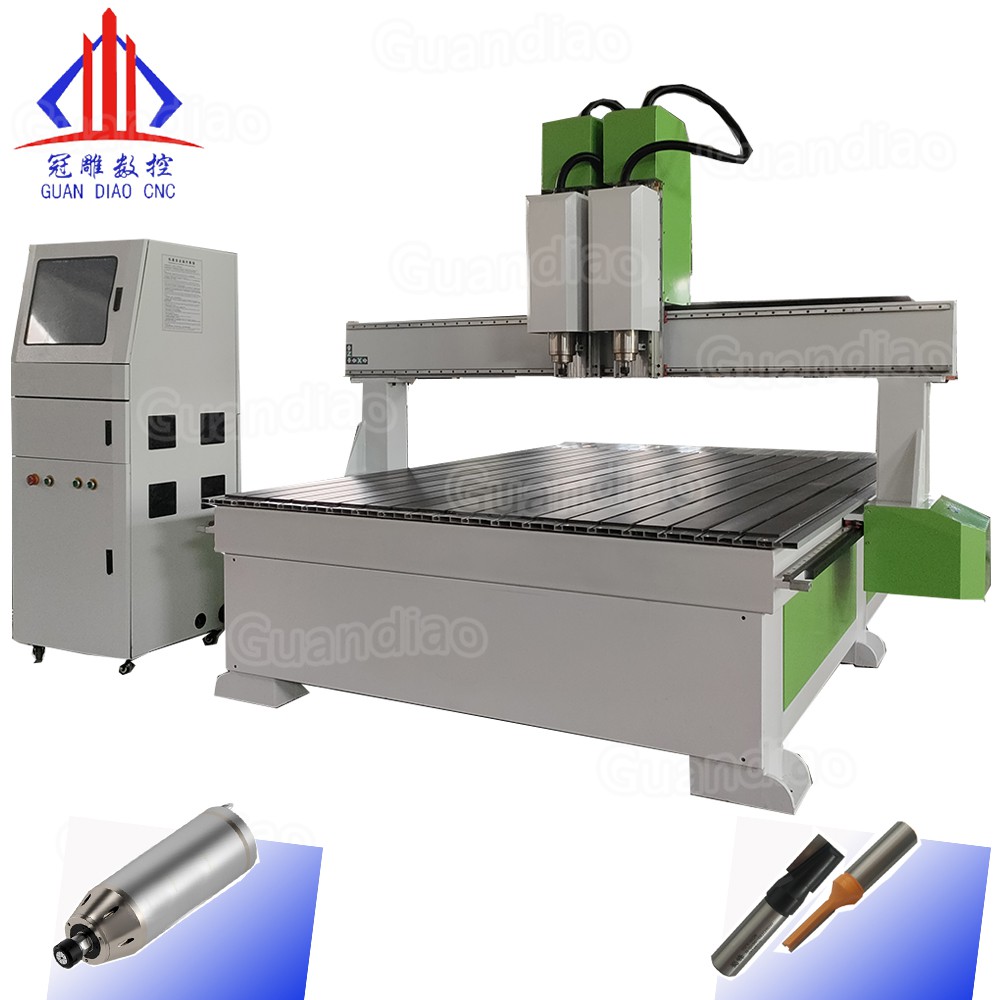

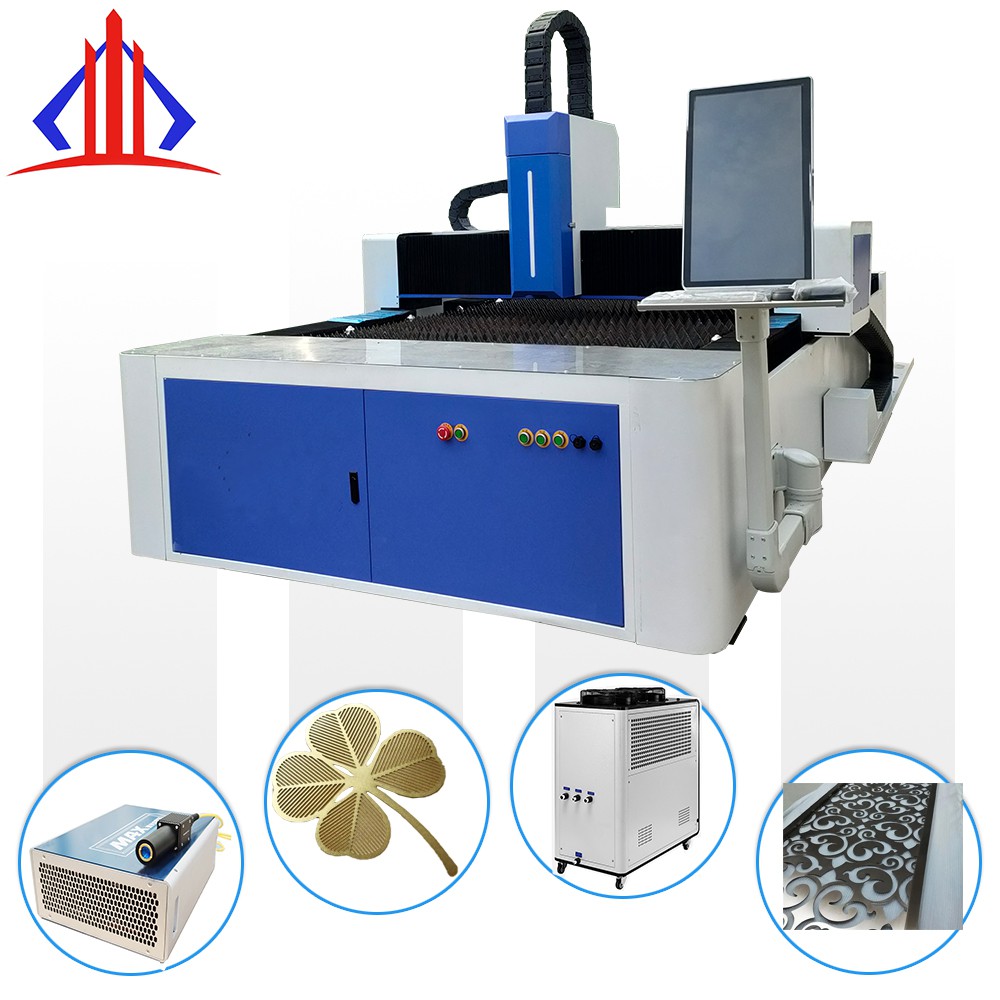

As the standard equipment of modern woodworking, CNC woodworking engraving machine is one of the essential woodworking tools.

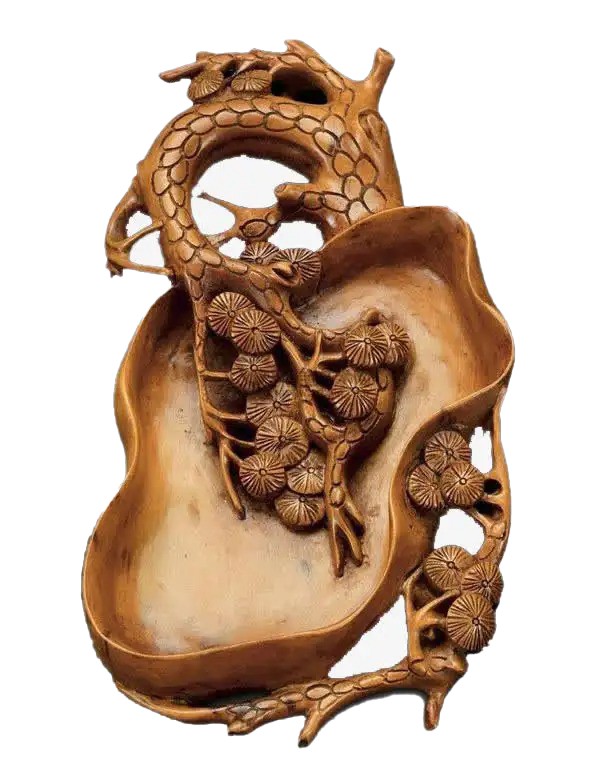

In addition to the basic functions of cutting, punching, carving and modeling, the computer numerical control woodworking engraving machine is favored by woodworking practitioners because of its simple operation, powerful practical functions and strong usability.

|  |  |

Look at the size of the manufacturer If you want to know which engraving machine brand is good, first look at the production and sales scale of engraving machine manufacturers. Many small manufacturers boast on the Internet. It is impossible to distinguish without on-the-spot inspection, so when purchasing, you must fully understand whether the selected one is Have visibility and view factory production workshop strength. | See Configuration Engraving machines with different production processes have great differences in price and function. Many customers are confused by the numerous quotations and do not know how to choose, but they need to keep in mind the eternal truth of "you get what you pay for". The price of engraving machines made by different configurations, assembly techniques and production processes will be worlds apart, as well as performance and quality. | Suitable Model The choice of engraving machine model is a very critical issue. It can be done through the working attitude of a company's sales staff and whether to ask the user whether the actual working conditions are carefully enough. If the sales staff does not understand clearly to the user before sales The working conditions are arbitrarily quoted, and such a manufacturer of engraving machines is not a good manufacturer. When selecting models for users, it is economical and practical to meet the processing requirements, and the quality is good. This is what a responsible engraving machine practitioner should do. |

High-quality engraving machine brand products must meet the customer's requirements for processing speed, processing accuracy and other process parameters, and also take into account the cost, comprehensive performance, reliability and other factors generated by the customer's use.

|  |  |

With the popularization of mechanization now, many factories are not satisfied with just using standard woodworking single-head engraving machines, so in line with the development of the market, customized machines such as multi-head woodworking engraving machines and trailer-mounted multi-head woodworking engraving machines are also gradually becoming popular. These customized machines It not only satisfies the efficiency of mass production for customers, but also greatly reduces the cost. The prices of these models are based on the actual needs of customers and the factory sales staff to discuss configuration and processing requirements, and the prices are also different.

Now let's take a closer look at the woodworking engraving machine configuration - the work surface.

Vacuum adsorption table VS ordinary table

1. Material fixation

The woodworking engraving machine of ordinary aluminum profiles uses fixtures to fix the material. After loading the material, the technicians fix the four sides of the plate through multiple fixtures, so that there will be no shaking during carving, resulting in errors in carving. For the vacuum adsorption table For the woodworking engraving machine, as long as the material is pushed onto the table, you don't need to worry about it, and you only need to push it lightly when cutting the material. One of the advantages of using a vacuum adsorption woodworking engraving machine is that it is convenient to load and unload and save time.

2. Price

The cost rises, and the price is naturally expensive. The vacuum adsorption woodworking engraving machine has an additional vacuum pump and a plastic board table, and the power of the spindle motor has also increased, so the price has increased by several thousand yuan. Of course, if it is made of wooden doors, cabinet doors and wardrobes , It is definitely not possible to use a woodworking engraving machine with ordinary countertops. You must choose a vacuum adsorption woodworking engraving machine.

3. Power consumption

Compared with the woodworking engraving machine on the aluminum profile table, it is obvious that the vacuum adsorption engraving machine consumes more power, so everyone should take this into account when considering the style selection.

Summary: Through the comparison between the ordinary tabletop and the vacuum adsorption tabletop of the woodworking engraving machine, it is found that there is a fundamental difference between the two. If it is mainly for hollowing and embossing, considering the cost performance, choose a woodworking engraving machine with an ordinary tabletop , If it is mainly wooden door cabinet doors and whole house customization, be sure to choose a woodworking engraving machine with vacuum adsorption countertops.

|  |  |

|  |  |

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb