GUANDIAO

The processing of panel furniture mainly includes three major technological processes: cutting, side hole punching, and edge sealing. Nowadays, CNC cutting machine is generally used for cutting, and fully automatic edge banding machine is used for edge sealing. With the development of science and technology, the cutting and punching equipment for panel furniture is constantly introducing new ones, and the functions of the equipment are constantly improving. The emergence of CNC six-sided drills has solved the overall hole position process problem in the production of panel furniture wardrobe cabinets, making the panel furniture production line truly automated and streamlined.

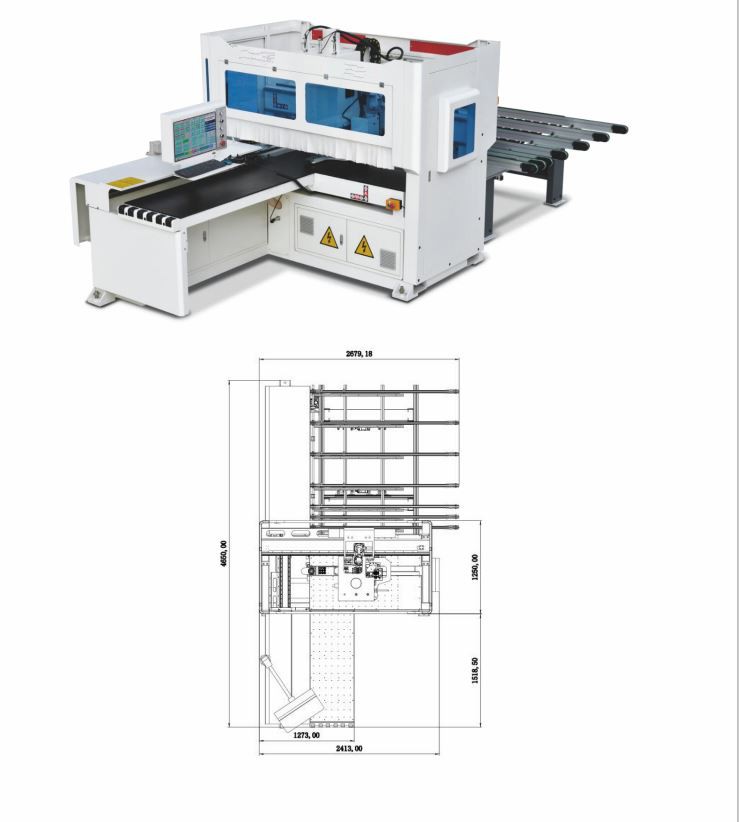

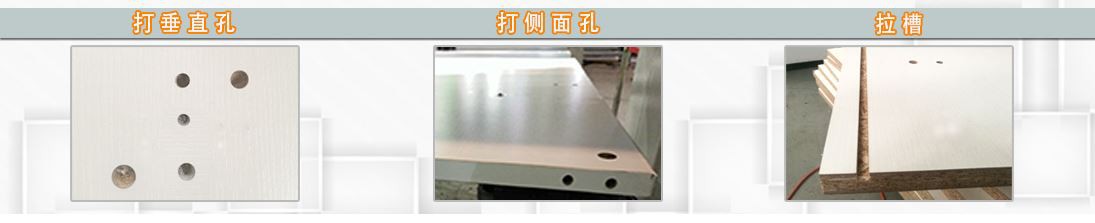

What is a six-sided drill?

The CNC six-sided drill is mainly used to solve the hole position process in the production of panel furniture, closet and cabinets. The six-sided drill can complete the processing of all the holes on the front and back of the workpiece and the four side holes at one time, so it is called the six-sided drill. With the use of CNC six-sided drill, there is no need to manually turn the plate during the cutting process. Now many small and medium-sized panel furniture factories are equipped with a combination of CNC cutting machine and side hole machine. Although this combination is low in cost, the degree of automation is relatively low. The loading and unloading machine, but because it is still manual flip, the labor intensity of the workers is still very large, and the assembly line is not consistent. The front end is used with a high-end CNC cutting machine or an electronic cutting saw to truly realize the intelligent production of panel furniture. The opening volume can reach 100-130 sheets in 8 hours a day. The automatic assembly line operation is simple and time-saving and labor-saving.

Is the six-sided drill efficient?

In terms of processing efficiency, because the laser side hole machine is still manual flipping, the labor intensity of the workers is still very large, and the assembly line operation is not consistent. With the use of CNC six-sided drills, the panel furniture production line is truly automated and streamlined. Ordinary cutting machine with side hole machine can process about 60 boards on average in 8 hours a day. Cutting materials with five-sided drill/six-sided drill, an average of about 120 boards can be processed in 8 hours a day.

How much is a six-sided drill?

In terms of production cost, the cutting machine and the side hole machine need about 200,000 yuan. It takes about 300,000 to 400,000 yuan for the cutting machine to match the CNC six-sided drill. The equipment cost has not doubled, but the production efficiency has been doubled. Moreover, due to the high degree of automation of the six-sided drill, manual pick-up is not required, saving Some operators are eliminated, which reduces labor costs.

All in all, if it is a general-scale furniture manufacturer with a small production volume, it can usually be completed by using a CNC cutting machine with a side hole machine and a fully automatic edge banding machine. However, for a manufacturer with a large production volume, it needs a CNC opening. The material machine is equipped with CNC six-sided drill and automatic edge banding machine, so that it can be more efficient and more accurate.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb