GUANDIAO

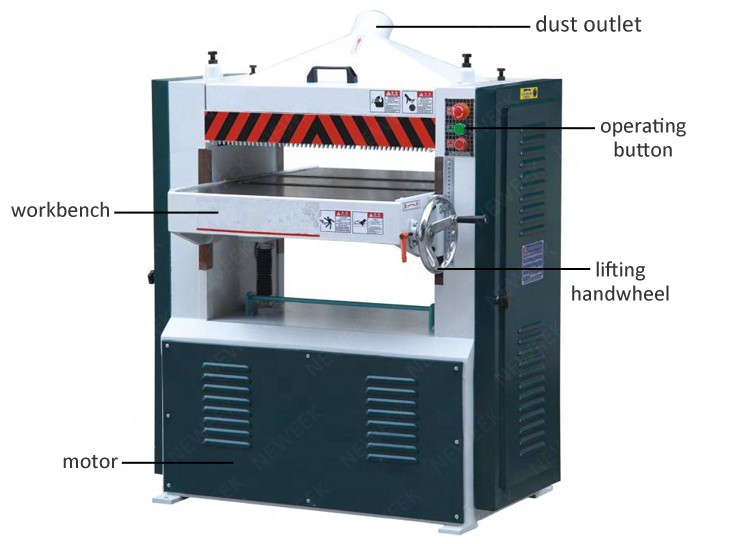

The planer: The planer is composed of a bed, a worktable, a worktable lifting mechanism, a cutter shaft, a pressing mechanism, a feeding mechanism, a transmission mechanism and an operating mechanism. The planer has a high degree of automation. It has developed single side planer, double side planer, four side planer, etc., with high processing efficiency.

The Press planing: The planer is generally composed of the bed, the front and rear worktables, the cutter shaft, the guide ruler, the transmission mechanism and the operating mechanism. As a basic planing machine, the operation is relatively simple, and it is also active in small and medium-sized woodworking workshops as the sawing and planing machine.

Difference: The wood is fed by external force when the planer is planing the wood. The machined surface of the wood is the datum plane. The planer has its own feeding mechanism. The other side of the machined surface of the wood is the datum plane. If the type of cutter shaft used by the planer and the planer is the same, the blades can be used interchangeably. If the type of cutter shaft used is different, confirm whether the blades can be interchanged according to the actual situation.

Automatic machine

Cutter cutting, reducing worker cost

Plane

The wood can be planed and straightened.

Flat cutting of plates

Decide how much wood can be sawed according to the power of the motor

Hole drilling

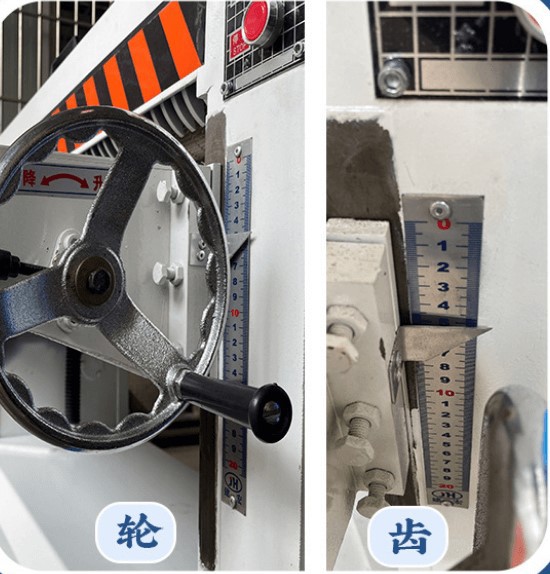

Internal drive structure

The equipment is driven by gear, with longer service life, more durability and more accuracy

Lifting gear

Fast adjustment, convenient operation

Removes 99.9% of airborne particles as small as 0.003 microns

With a sensitive de-allergen mode, product can effectively detect and reduce allergens such as pollen. Hypoallergenic certified by ECARF (European Allergy Research Foundation).

Single side press planing introduction: It adopts a piano key type pressing mechanism with a protective cover, which has good performance, and the pressure of each piano key can be adjusted independently. The body structure is rigid, and the planing stability is excellent. Large worktable with stable wood support. After grinding and dynamic balance calibration, it operates smoothly. The feeding end is equipped with anti rebound pawl to effectively avoid the danger of workpiece rebound. The height of the worktable shall be adjusted by hand wheel. The worktable is equipped with front and rear rollers to ensure the smoothness of workpiece feeding.

The segmented spiral pressing and feeding roller can safely and high-speed plane multiple uneven wood pieces at the same time, and the processed workpiece is accurate and smooth

Heavy press planer, the main structure of the machine body is all cast iron, which is more durable

The lower planer table can be independently lifted and adjusted to effectively control the depth of the lower planer. Say goodbye to the backward design that the lower planer cannot be adjusted when it is fixed, so that the product can effectively avoid waste of the processed workpieces

This product adopts cast iron body, with special high-power motor. The whole machine has been checked for multiple times of dynamic balance, making the whole machine run more stable and effectively improving product quality and output. Special automatic cleaner

The cutter shaft has a spring, which makes tool change very convenient.

Shandong Guandiao CNC Equipment Co., Ltd. is a scientific and technological enterprise specializing in the R&D and manufacturing of automatic woodworking equipment and laser CNC equipment. After nearly 10 years of development experience, the company has 36000 square meters of modern chemical plants in the beautiful spring city of Jinan, and has become a reliable and trustworthy CNC machine manufacturer both at home and abroad. Our main products include ATC CNC machining center, 4-axis CNC machining center, high-end customized furniture production line, CNC six side drill, CNC machining center, CNC side hole machine, edge banding machine, sliding table saw, coating machine, polishing machine, optical fiber cutting machine, laser engraving machine, stone CNC machining center, vibrating knife cutting machine, plasma cutting machine, 3D scanner and other woodworking machinery. These devices are used in industry, handicraft and art industries around the world. It includes woodworking, metal and stone processing, aluminum manufacturing, machining, mold manufacturing, etc.

With product quality as the core and customer demand as the basis, the company adheres to the business philosophy of "using world advanced technology to create quality for users", serves customers, builds products with strength, and builds brands with credibility. Shandong Guandiao CNC Equipment Co., Ltd. is willing to cooperate sincerely with friends from all walks of life to achieve common development!

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb