GUANDIAO

1906, in Berlin, Germany: To complete his own furniture design, Wilhelm. Mr. Odendo invented the world's first sliding table saw, which made sawing wood fast and precise. Since then, table saws have spread rapidly all over the world.

| The main structural feature of the panel saw is the use of two saw blades, the main saw blade and the scoring saw blade. When cutting, the scribe saw cuts in advance, and cuts a groove with a depth of 1-2mm and a width of 0.1-0.2mm thicker than the main saw blade on the bottom surface of the processed plate to ensure that the main saw blade The edge of the kerf does not tear when cutting, resulting in a good sawing quality. The diameter of the scribing saw blade is small, usually about 120mm, driven by a separate motor. The saw blade speed is generally above 9000r/min, and the cutting speed is generally 56-60m/s. The power of the main motor is generally 4 ~ 9kw. A special V-belt is used for easy speed regulation, ensuring that a single belt can meet the required power transmission. The speed of the main saw blade is generally 3000-6000r/min, and the distance between the main saw blade and the scribing saw blade is generally about 100mm. |

|

Purpose: Simply put, it is fast and precise sawing wood. (1) The operation is easy and labor-saving, and the pushing stroke is large. (2) With a stable and light trailer, it runs smoothly. (3) The setting of the mobile workbench and the main saw blade can be adjusted by 45 degrees, which expands the scope of use of the saw machine. |

A. plate should be close to the block and cannot be moved;

B. Adjust the cutting speed according to the thickness and hardness of the plate, and push the machine tool at a constant speed, not too fast or too fast.

C. When cutting small materials, use wooden strips to push forward.

D. Operators should wear masks, gloves, loose clothes, and long hair.

E. Do not use your hands to take objects directly beside the rotating saw blade. If necessary, you can use other long accessories to push it away before taking it.

F. If the edge corner of the board is defective, you should consider replacing the saw blade.

G. After the cutting task is completed, turn off the power, and do a good job of 5S on the saw table and its surroundings.

In addition to completing the necessary control tasks, the operator of the sliding table saw has to overcome the unfavorable posture of standing and bending for a long time, as well as the impact of the adverse working environment such as manual lifting with heavy load, vibration and noise on the body. In the woodworking sliding table saw operation position, the problem of work fatigue is particularly serious. The work fatigue in this position will not only lead to a decrease in work efficiency, but also may lead to human error accidents and waist injuries of operators, and the fatigue of many people may also cause hidden dangers of accidents.

Saw Blade

Control Panel

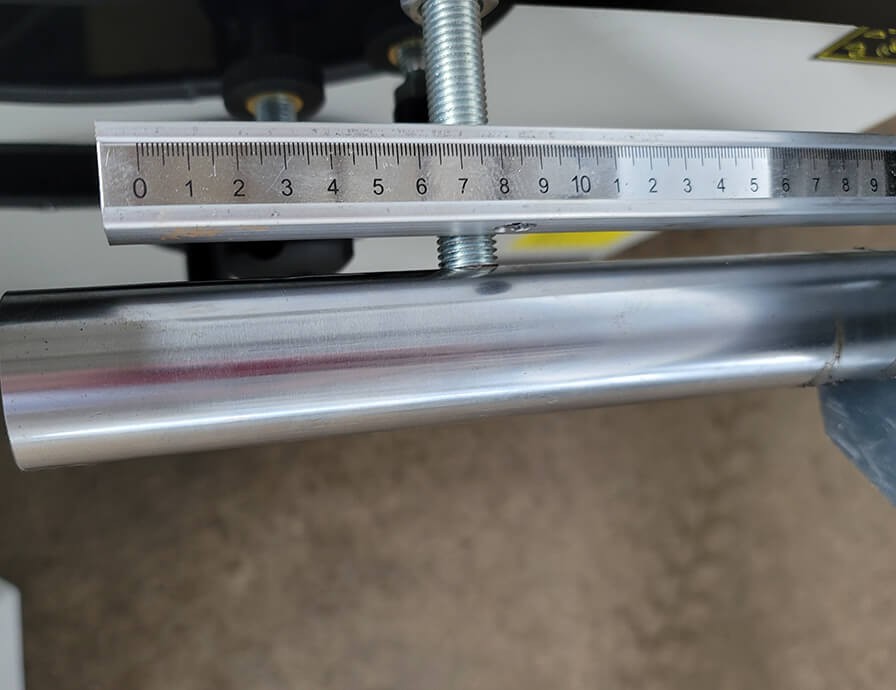

Scale ruler

Maintenance procedures

1. Before starting any maintenance work, turn off the main switch, cut off the power supply and hang the sign of "in maintenance, it is strictly forbidden to close the switch", and take certain safety inspection measures before working. After each work is completed, turn off the main switch.

2. When cleaning machine parts, use or do not use flammable fluxes with caution. Remove or trap saw blades before performing maintenance work.

3. According to the machine use requirements and operating procedures, the machine is regularly maintained

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb