GUANDIAO

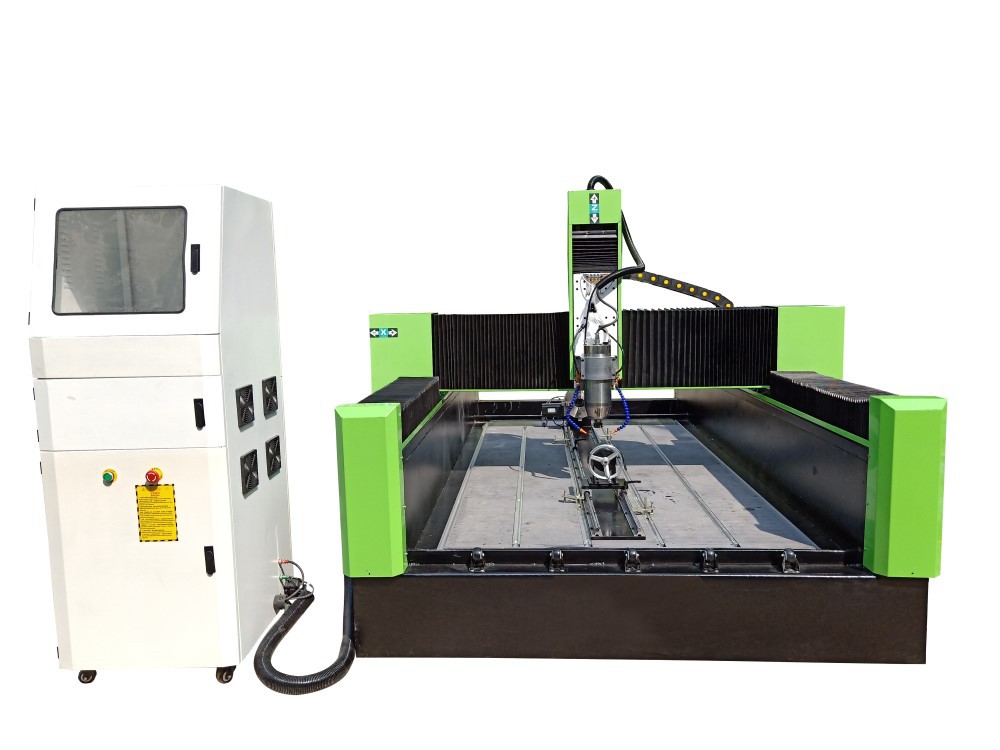

Stone carving machine equipment has been widely used in various stone carving industries. It can be widely used mainly because of its own advantages and characteristics, such as convenience and high efficiency. In the application industry, we find that most of them are used in the processing of marble and granite table panels, washbasins, special-shaped lines, columns, Roman columns, column bases, column caps and various special-shaped revolving products.

1. It has strong adaptability to the processing object, adapts to the characteristics of single piece production of mold and other products, and provides a suitable processing method for mold manufacturing;

2. High machining accuracy and stable machining quality;

3. Multi-coordinate linkage can be carried out, and parts with complex surface can be processed;

4. When processing parts are changed, generally only the NC program needs to be changed, which can save production preparation time;

5. The machine tool itself has high accuracy and rigidity. It can choose favorable processing consumption and high productivity (generally 3~5 times of that of ordinary machine tools);

6. The machine tool has a high degree of automation, which can reduce the labor intensity;

7. It is conducive to the modernization of production management. CNC machine tools use digital information and standard code to process and transmit information. The computer control method is used to lay the foundation for the integration of computer-aided design, manufacturing and management;

The main features of the stone carving machine are as follows:

1. The frame adopts a one-piece structure with good rigidity and no deformation.

2. The spindle adopts high-precision and high-performance two-door electric spindle with low machining vibration and high rotation accuracy.

3. Each main motion guide adopts linear guide rail with low resistance and high accuracy.

4. Each control axis adopts Japanese Yaskawa servo motor and driver.

5. Various tools are designed for workpiece clamping to facilitate operation.

6. External cooling and internal cooling can be adopted for tool cooling as required.

7. It is convenient to process the guide surface of the washbasin.

8. The semi-floating connection with advanced technology is adopted between the beam and the frame, thus ensuring the stability of operation.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb