GUANDIAO

|

|

Reverse engineering (also known as reverse technology) is a product design technology reproduction process, that is, reverse analysis and research on a target product, so as to deduce and obtain the processing flow, organizational structure, functional characteristics and technical specifications of the product, etc. design elements to produce products that are similar in function but not identical. Reverse engineering originated from hardware analysis in the commercial and military fields. Its main purpose is to deduce the design principle of the product directly from the analysis of the finished product when the necessary production information cannot be easily obtained.

High-tech 3D scanning for reverse engineering is a technology that captures the 3D data of objects by using lasers or structured lights, from which you can obtain information about their shapes and dimensions.

From 3D scanning, users can obtain point clouds that represent the surfaces of objects and can be converted into mesh models.

|

|

|

Non-contact 3D Laser Scanners: Non-contact handheld 3D laser scanners for reverse engineering mainly fall into two categories, 3D laser scanners, and structured-light 3D scanners. By emitting laser beams onto the objects, professional 3D laser scanners can obtain the coordinates of points on the surfaces and objects.

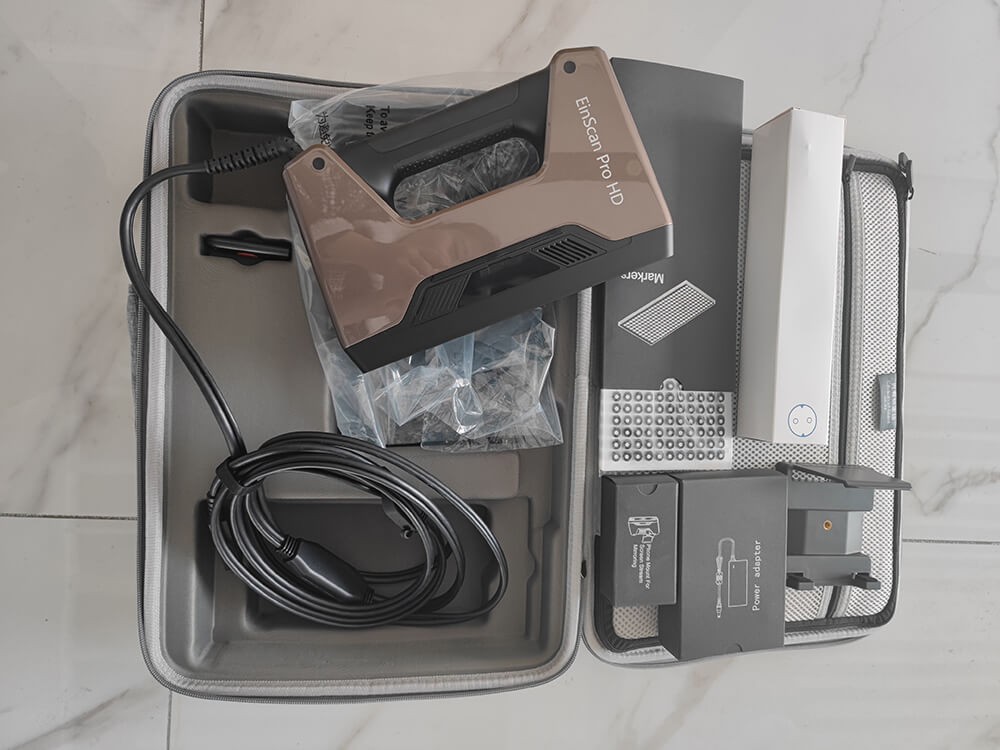

Industrial 3D Scanners for Reverse Engineering

The handle 3d scanner series 3D laser scanner is the first that combines infrared and blue lasers into one single instrument.

It offers five standard working modes:

♦ Large-area scanning

♦ Fast scanning

♦ Fine scanning

♦ Deep-hole scanning

♦ Built-in photogrammetry system.

With two sets of high-definition industrial cameras, it can conduct 3D scanning meticulously. It is suitable for backward engineering in industries such as manufacturing, energy, automotive, and rail transportation.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb