GUANDIAO

Fiber laser welding machine is a device that uses a fiber laser as an energy source to weld workpieces using a high-energy density laser beam. It is usually used for high-precision welding processes and can achieve precise welding of various metal materials. It has the advantages of fast welding speed, small heat affected zone, and high weld quality.

Fiber laser welding machine is a device that uses fiber laser as an energy source, mainly used for welding workpieces. It utilizes high-energy density laser beams to achieve high-precision welding processes, suitable for various metal materials, and has the advantages of fast welding speed, small heat affected zone, and high weld quality.

Fiber laser welding using different metals, component shapes, sizes, and volumes has been successfully applied in many industries.

01

Battery welding

Laser welding of aluminum alloy and pure copper to form electrical contact with the positive and negative electrodes of the battery. All materials and material combinations used in batteries are candidate materials for the new fiber laser welding process.

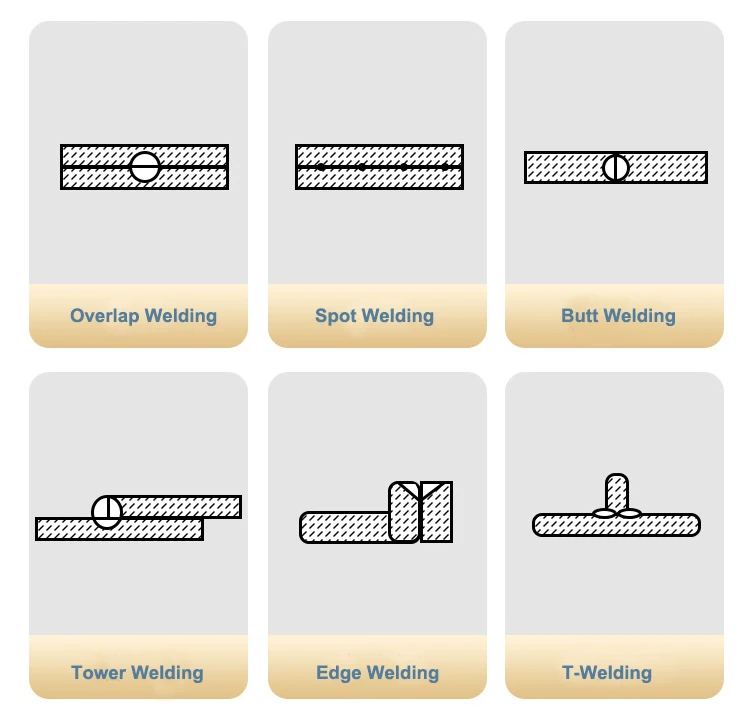

The overlapping, docking, and fillet welding joints enable various connections inside the battery. Laser welding of the connector material to the negative and positive terminals will generate electrical contact in the packaging. The final assembly welding step of the battery pack, which involves sealing the seams of the aluminum cans, creates a barrier for the internal electrolyte.

02

Precision machining welding

Seals used in ships, chemical refineries, and the pharmaceutical industry were initially TIG welded. Due to their use in sensitive environments, these components are precision machined and ground from nickel based alloy materials that are resistant to high temperatures and chemical corrosion. At present, the assembly of these components has been improved using fiber laser welding.

The reasons for replacing early robotic arc welding processes with fiber laser welding include:

The quality of laser welding is consistent; Easy to transition from one component configuration to another, reducing setup time and increasing productivity; And by assembling laser tracking sensors to automate the laser welding process and reduce costs.

03

Dissimilar metal welding

The ability to manufacture products using different metals and alloys greatly enhances the flexibility of design and production. Optimizing the performance of finished products, such as corrosion, wear, and heat resistance, while controlling costs, is a common motivation for dissimilar metal welding.

Connecting stainless steel and galvanized steel is an example. Due to their excellent corrosion resistance, 304 stainless steel and galvanized carbon steel have been widely used in various applications, such as kitchen utensils and aviation components. This process presents some special challenges, especially as zinc coating can cause serious weld porosity issues.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb