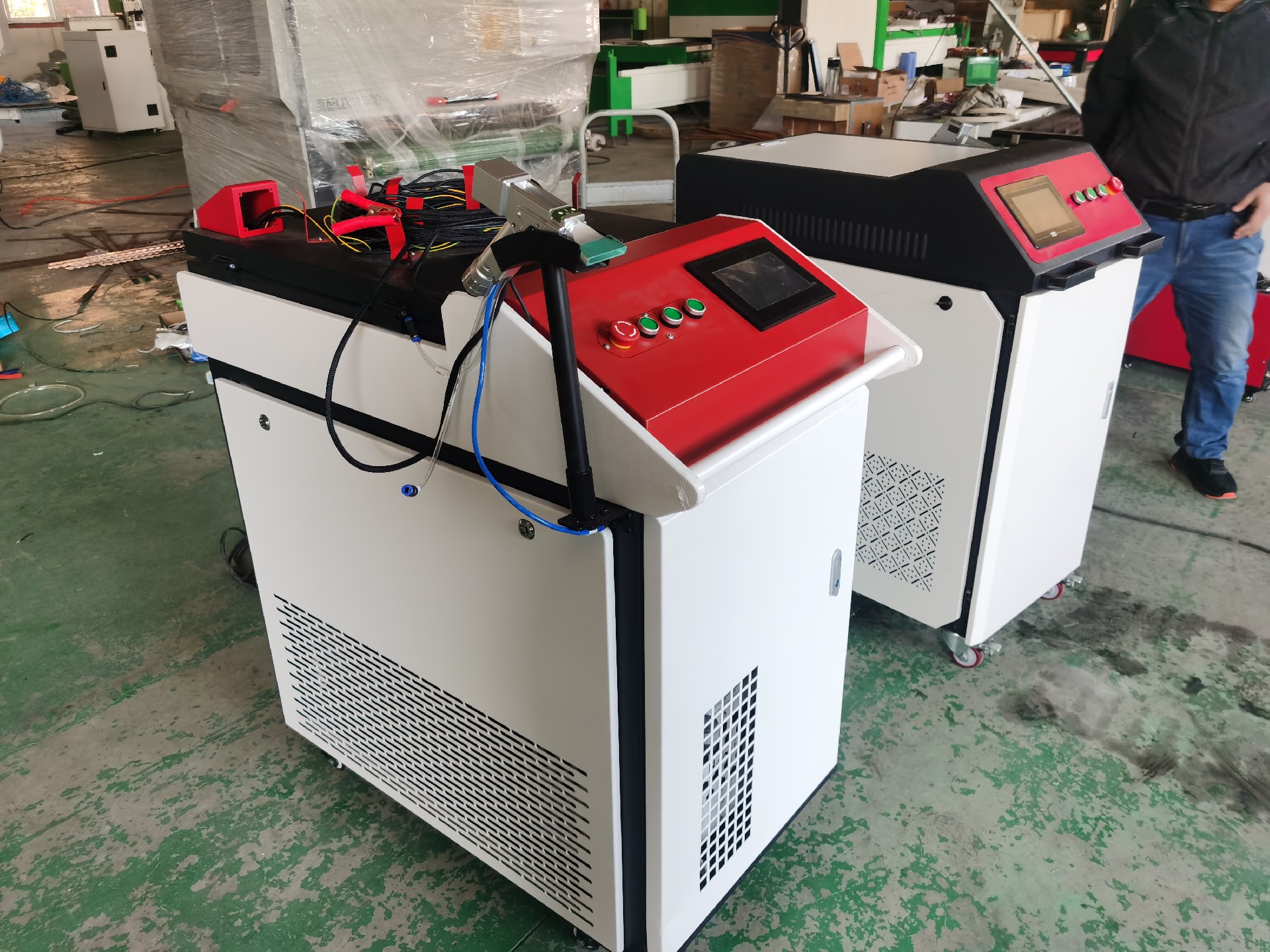

GUANDIAO

Laser cleaning machine is a device that uses laser technology for surface cleaning. It targets the surface of an object with a high-energy laser beam, evaporates or peels off materials with poor physical properties such as dirt, coatings, or oxides, thereby achieving the effect of cleaning and removing dirt. This technology is commonly used to clean metal surfaces, such as removing paint, oxide layers, or cleaning welded joints.

The advantages of laser cleaning machines include:

1. * * Non contact * *: Using a laser beam for cleaning eliminates the need for physical contact, avoiding surface wear and damage.

2. * * High precision * *: The laser beam can accurately aim and clean specific areas without affecting the surrounding area.

3. * * Efficiency * *: Laser cleaning can quickly remove dirt and improve cleaning efficiency.

4. * * Environmental Protection * *: Compared to traditional cleaning methods, laser cleaning usually does not require chemical cleaning agents, reducing environmental pollution.

5. * * Multifunctionality * *: It can be applied to different types of materials and surfaces, such as metals, plastics, etc., with a wide range of applicability.

6. * * Energy saving * *: Laser cleaning machines are usually able to control energy consumption during the cleaning process and have a high energy efficiency ratio.

These advantages make laser cleaning machines have broad application prospects and market demand in industrial production and maintenance fields.

Laser cleaning machines have applications in many different fields, and the following are some main usage scenarios:

1. Cultural Relics Protection: Laser cleaning can remove dirt and corrosive substances from the surface of cultural relics without damaging fragile surfaces.

2. * * Automotive Industry * *: Used to clean engine components, body coatings, or remove defects from car paint.

3. * * Aerospace * *: Used for cleaning aviation components, such as aircraft surfaces and engine components, as well as cleaning satellite components with high precision requirements.

4. * * Steel Industry * *: In the steelmaking process, it is used to remove the oxide scale on the surface of steel and improve product quality.

5. * * Textile industry * *: Used to remove oil or other stains from the surface of textiles.

6. Precision manufacturing: For electronic components, optical lenses, etc., laser cleaning can remove dirt generated during the production process or long-term use, maintaining the cleanliness and performance of the product.

7. * * Surface engineering * *: such as pre-treatment of coatings, removal of coatings, etc., to achieve better coating effects.

8. * * Medical equipment * *: Used for cleaning medical devices, especially fine components that are difficult to clean with traditional methods.

9. * * Ship Painting * *: Laser cleaning of the hull surface to remove old paint and corrosion layers for new painting.

10. * * General industry * *: Clean the surface of pumps and valves, pipeline systems, hydraulic components, etc.

The application of laser cleaning machines is constantly expanding, and with technological progress and cost reduction, more fields will benefit from this technology.

Copyright © 2024 Shandong Guandiao CNC Equipment Co., Ltd. . | All Rights Reserved Technical support:Xintuweb