Multi-function Sliding Table Saw

The main machine part of the sliding table saw includes bed, worktable, longitudinal and cross-sectional guide plate, main saw, marking saw, transmission and other parts. The structure and working principle are similar to that of ordinary circular saw, and can be used as ordinary circular saw alone.

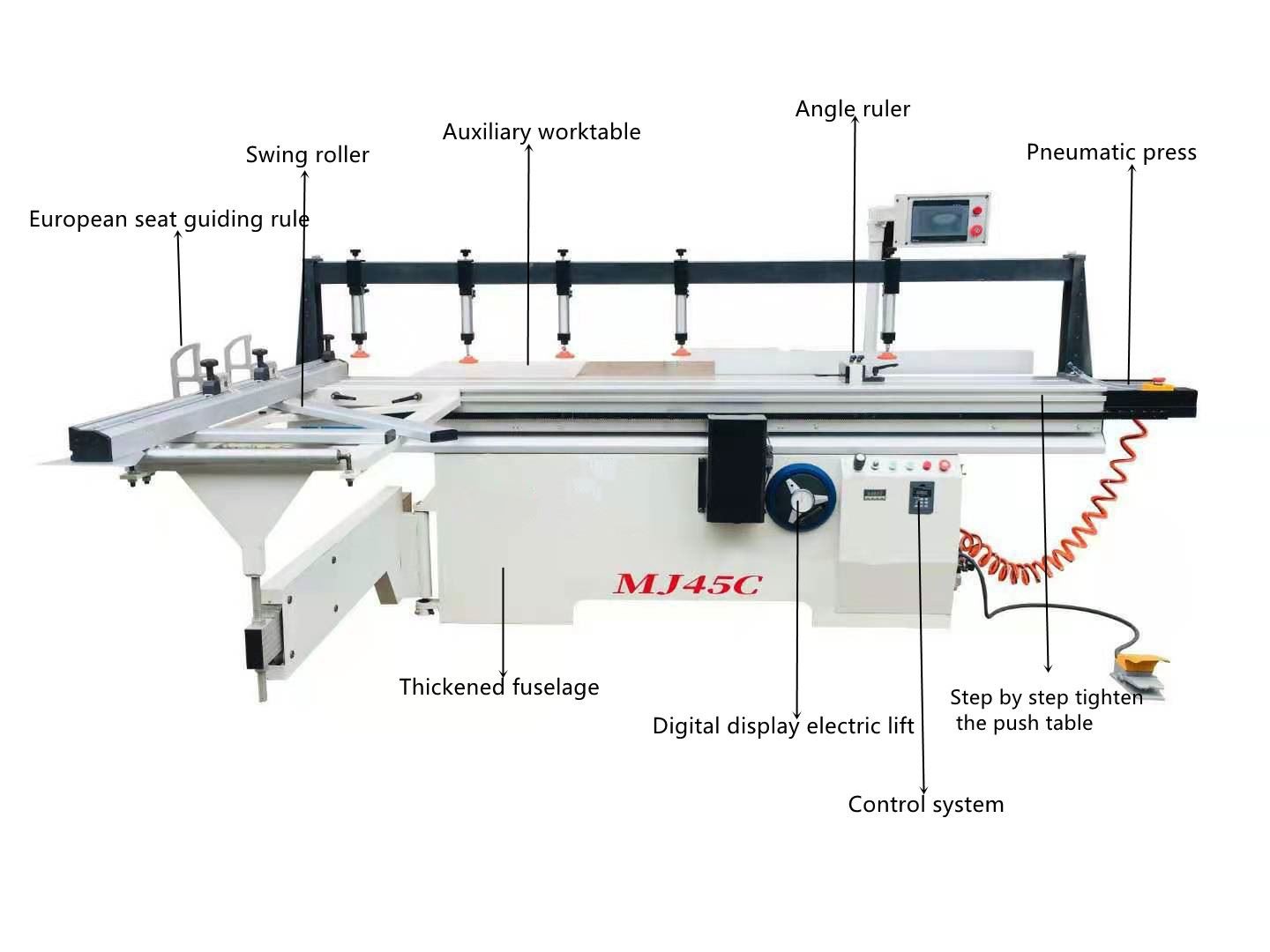

Composition of sliding table saw:

1. Rack; 2. Main saw part; 3. Slot saw part; 4. Transverse guide baffle; 5. Fixed workbench; 6. Sliding sliding sliding table; 7. Diagonal saw guide plate; 8. Bracket; 9. Angle display device of diagonal saw; 10. Lateral guide baffle.

The main structural feature of the sliding table saw is the use of two saw blades, namely, the main saw blade and the marking saw blade. When cutting, the scribe saw shall cut in advance, and the groove with depth of 1 ~ 2mm and width of 0.1 ~ 0.2mm thicker than the main saw blade shall be cut on the bottom surface of the processed plate, so as to ensure that the edge of the saw mouth will not be torn during cutting of the main saw blade, so as to obtain good sawing quality. The diameter of the scribing saw blade is small, usually about 120mm, and is driven by a separate motor. The rotating speed of the saw blade is generally above 9000r / min, and the cutting speed is generally 56 ~ 60m / s. The scribing saw blade shall be aligned with the main saw blade in the same vertical plane. Diameter of main saw blade & 8943; It is generally 300 ~ 400mm and is driven by the main motor through V-belt. According to the different diameter of the main saw blade and the type of processed plate, the main saw blade can be changed by using the tower wheel. The tower wheel has simple speed change structure and belongs to constant power output, which is more in line with the actual needs of wood processing. The power of the main motor is generally 4 ~ 9kw. In order to make the speed regulation simple, special V-belt is adopted to ensure that a single belt can meet the transmission of required power. The rotating speed of the main saw blade is generally 3000 ~ 6000r / min, and the spacing between the main saw blade and the marking saw blade is generally about 100mm.

Another main structural feature of the sliding table saw is that the marking saw blade and the main saw blade are fixed, and the moving worktable made of aluminum profile containing the processed plates is pushed back and forth by hand to realize sawing. Due to the special structure of the guide rail of the mobile worktable, it is light and labor-saving when manually pushing and feeding, and the machining accuracy is very high.

The bed of the sliding table saw is mostly welded from steel plate with a thickness of 5 ~ 6mm, which is stable and beautiful, and can ensure that its early sawing processing does not produce inclination and distortion. The fixed worktable is fixed on the top of the bed. The cast parts of Sichuan are required to be flat and not deformed, and are equipped with longitudinal cutting guide plate and its adjustment mechanism.

Specification

Technical Parameters |

Product name | 45 Degree Electric Lifting and Cutting Board Saw |

Diameter of main saw | 300mm |

Main saw speed | 4000/6000/min |

Main saw power | 5.5kw |

Side Saw Diameter | 120mm |

Auxiliary saw power | 1.1kw |

Voltage | 380V |

Weight | 800kg |

Size of the whole machine | 3000*1100*1200mm |

Details

Electric lift Export lifting mode for electric lifting angle display for digital reading, plus accuracy and convenience. |

Step by step tighten the push table The adoption of the sharing platform makes it more stable and unstable deformation. The accuracy is more accurate by using Taiwan imported round bar double guide rail. The platform is step by step, cutting more precise. |

All copper motor The motor uses 5.5kw-1.1kw, aluminum shell all copper national standard motor to provide strong power for the machine. |

Convenient oil filling cup The lubrication mode of the export type push table saw is oil cup filling, and the ordinary type needs manual oil injection. |

Application

Applicable products:

MDF,particleboard,wood-based panels,ABS panels,PVC panels,plexiglass,solid wood and other wood structure and hardness similar to the plate.

Packing&Shipping

Company profile

FAQ

Why to choose Guandiao CNC?

1.As alibaba's star supplier, we have Alibaba Trade Assurance to make sure the buyer's benefit. lf can’t meet the details in the contract,100% of your payment will be returned.

2.As a professional manufacturer, we have 13 years factory experience for woodworking machinery. from parts processing and production to the whole machine assembly and sales,professional, dedicated and efficient. providing customers with one-stop service.

3. With more than 10 R&D staff and senior engineers. Support equipment programming and function customization. meet different customer' s needs.

4.Adopt first-class processing equipment, advanced manufacturing technology. More and more customers are using our machines, and we receive good comments and feedback from many countries.

5.We have perfect after-sales service.

6.Excellent location,only one hour to Qingdao Port.

Hot Tags: multi-function sliding table saw, China, suppliers, manufacturers, factory, price, wholesale, for sale, CNC Router Table Saw, Sliding Table Saw, Table Saw, CNC Panel Saw, Panel Saw, Woodtech Panel Saw