Panel table saw

Structural features

The moving table is the key part of the sliding table saw and the main part different from the ordinary circular saw. The moving table is composed of bracket, lower guide rail, roller, sliding table and so on.

Its remarkable features are: (1) light and labor-saving operation, large driving stroke and large cutting width; (2) It is equipped with a stable and light trailer, which runs smoothly; (3) The setting of the mobile workbench and the main saw blade can be adjusted 45 degrees, which expands the application range of the saw. Some saw machines are also equipped with milling devices, which can process grooves and grooves with a width of 30-50mm.

Operation characteristics of sliding table saw

Fine cutting panel saws are subject to dynamic balance or static balance. Generally, they do not need a foundation and can be added on a flat ground. During machining operation, the workpiece is placed on the mobile workbench and pushed manually to make the workpiece realize feed movement. The operation is very convenient and flexible. During operation, pay attention to safety at all times to prevent accidents.

Main technical parameters of sliding table saw

The specifications of the sliding table saw have been formed into a series, and the main parameters are the maximum sawing length, which generally ranges from 2000 to 5000 ram. China's industrial standard JB / t9950-1999 parameters of woodworking sawing machine with movable worktable stipulates that there are T3 specifications of 2000mm, 2500mm and 3150mm.

Direction of efforts in designing sliding table saw

Since the early 1980s, China has introduced, mapped and produced push table saws. More than 20 woodworking machinery manufacturing enterprises have produced push table saws, with an annual output of about 4000 sets, which has basically replaced imported products to meet domestic demand.

Most of the enterprises producing push table saws in China start the design of push table saws from surveying and mapping foreign prototypes, and then improve them according to the problems in their use. Some stress relations are not well understood and there is blindness. The vast majority of enterprises have not carried out static and dynamic mechanical calculation, and lack of necessary theoretical basis. In order to improve the shortcomings in the design and design a push table saw with good performance, it is suggested that the main production enterprises of panel saw should adopt the internationally popular CAD design, optimization design and dynamic design on the basis of summarizing the existing experience, and carry out pilot test. With the rapid development and application of juice calculator, the calculation technology is gradually mature. The stress of push table saw under various complex stress conditions is calculated by using limited software. As far as the main saw blade and scribe saw blade are concerned, their shapes are not complex. They can be approximately regarded as elastomers to calculate the vibration characteristics of stress. At the same time, they cooperate with the test and analysis technology card to obtain modal parameters and improve the calculation accuracy. On this basis, the commercial software for the design and manufacture of push table saw can be developed, so as to design and manufacture a high-level push table saw on the basis of real theoretical basis.

Specification

Mode | 2.8m 45° MJ45YD | 2.8m 90° MJ90YD | ||

Dimension of sliding table | 2800X320mm | 2800*320mm | ||

Length of cut between saw blade and rip fence | 2750mm | 2750mm | ||

Width of cut between saw blade and rip fence | 1250mm | 1250mm | ||

Saw blade diameter | 300mm | 300mm | ||

Height of cut | 80mm | 80mm | ||

Speed of main saw spindle | 4000/6000rpm | 4000/6000rpm | ||

Main spindle diameter | 30mm | 30mm | ||

Tilting saw blade | 0-45° | 90° | ||

Main motor | 4.0/5.5kw | 4.0/5.5kw | ||

Scoring saw blade diameter | 120mm | 120mm | ||

Speed of scoring saw blade | 8000rpm | 8000rpm | ||

Scoring saw diameter | 20mm | 20mm | ||

Scoring motor | 0.75/1.1kw | 0.75/1.1kw | ||

Overall dimension | 2850*3050*900mm | 2850*3050*900mm | ||

Machine Details

Electric lift Export lifting mode for electric lifting angle display for digital reading, plus accuracy and convenience. |

45°/90° saw This machine can adjust 45° or 90° saw tooth,suitable for more range of wood use. |

Round guide rail The double-layer round bar guide rail push table has stable structure,high pressure bearing and guaranteed precision. |

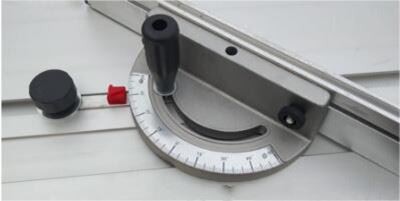

Ruler The operation is simple and clear to ensure the machining accuracy. |

Application

Apply to processing all kinds of density boards, shaving boards, wood-based panels, ABS panels, PVC panels, organic glass plates and solid wood and others with wood structure and similar hardness.

Packing&Shipping

Company profile

Our company’s leading products: CNC panel saws, full range of Edge banding machines, CNC six sidesdrilling machines, CNC, cutting machines, automatic connection, CNC side hole drilling machines, etc.We provide professional one-stop production line services for the panel furniture industry: professional production line planning services, professional production line equipment customization services, professional production line automation program services, and professional production line section staff program services.

FAQ

Q:What’s your MOQ and delivery?

A:Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price send to you.

Q: How is your after sales service?

A: Our sales are online for 24-hours. We can also supply overseas install service.

Q: If my machine is broken. Can you repair it for me?

A: Yes. We have free training online. If there is big trouble with your machine in the warranty time, we can repair it.

Hot Tags: panel table saw, China, suppliers, manufacturers, factory, price, wholesale, for sale, CNC Router Table Saw, Sliding Table Saw, Portable Table Saws, CNC Panel Saw, Wood Panel Saw, CNC Table Saw