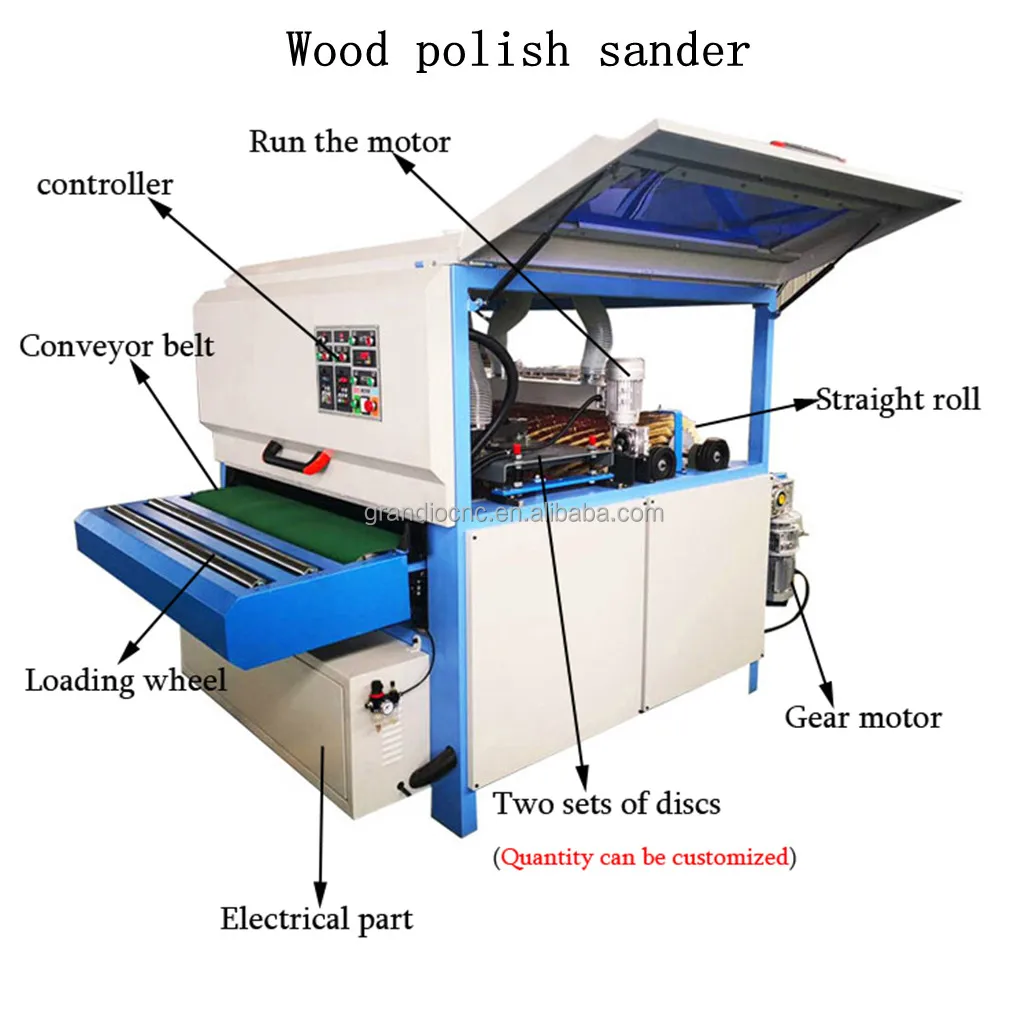

Woodworking Panel Polishing Sanding Machine

Working principle:

The key to the operation of the polishing machine is to try to obtain the maximum polishing rate so as to remove the damaged layer during polishing as soon as possible. At the same time, the polishing damage layer should not affect the finally observed tissue, that is, it will not cause false tissue. The former requires the use of coarse abrasive to ensure a large polishing rate to remove the polished damage layer, but the polishing damage layer is also deep; The latter requires the use of the finest material to make the polishing damage layer shallow, but the polishing rate is low.

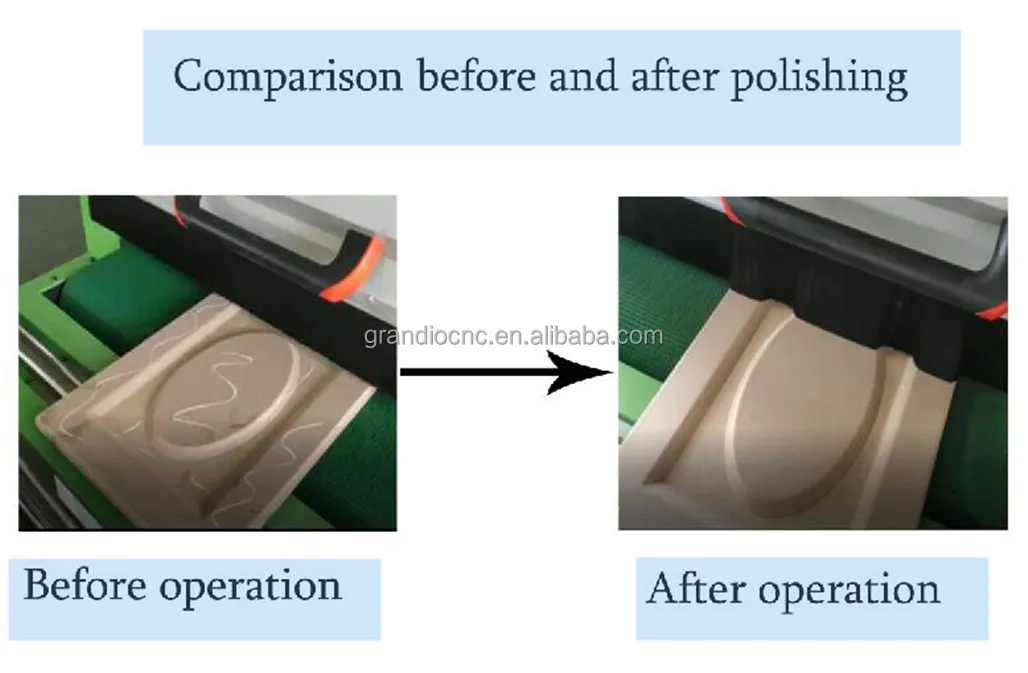

The best way to solve this contradiction is to divide polishing into two stages. The purpose of rough polishing is to remove the polishing damage layer. This stage should have the maximum polishing rate. The surface damage formed by rough polishing is a secondary consideration, but it should also be as small as possible; The second is fine polishing (or final polishing), which aims to remove the surface damage caused by rough polishing and minimize the polishing damage. When polishing with the polishing machine, the grinding surface of the sample and the polishing disc shall be absolutely parallel and evenly pressed on the polishing disc, and attention shall be paid to prevent the sample from flying out and generating new grinding marks due to too much pressure. At the same time, the sample shall also rotate and move back and forth along the radius of the rotary table to avoid local wear of the polished fabric too fast. During the polishing process, micro powder suspension shall be continuously added to keep the polished fabric at a certain humidity. Too high humidity will weaken the grinding mark effect of polishing, make the hard phase in the sample appear convex, and the "trailing" phenomenon of non-metallic inclusions in steel and graphite phase in cast iron; When the humidity is too small, the friction heat will raise the temperature of the sample, reduce the lubrication effect, lose the luster of the grinding surface, and even appear black spots, and the light alloy will damage the surface. In order to achieve the purpose of rough polishing, the rotating speed of the rotary table is required to be low, preferably not more than 600r / min; The polishing time should be longer than the time required to remove the scratch, because the deformation layer should also be removed. After rough polishing, the grinding surface is smooth but dull. Uniform and fine grinding marks are observed under the microscope and need to be eliminated by fine polishing.

During fine polishing, the speed of rotary table can be appropriately increased, and the polishing time is appropriate to throw away the damaged layer of coarse polishing. After fine polishing, the grinding surface is as bright as a mirror, and no scratches can be seen under the bright visual field of the microscope, but the grinding marks can still be seen under the phase contrast lighting. The polishing quality of the polishing machine seriously affects the microstructure of the sample, which has gradually attracted the attention of relevant experts. A lot of research work has been done on the performance of polishing machines at home and abroad, and many new models and new generation polishing equipment have been developed from the original manual operation to a variety of semi-automatic and full-automatic polishing machines.

Model | GD-630 | GD-1000 | GD-1300 | |

Working width | 30-630mm | 30-1000mm | 30-1300mm | |

Size of Abrasive Belt | 650*1900mm | 1020*2000mm | 1320*2200mm | |

Working thickness | 2-100mm | |||

Feeding speed | 5-25m/min | |||

Inverter | 5.5KW+1.5kw | |||

Reducer motor | 1.5kw | |||

Total power | 11kw | |||

Air pressure | >0.55Mpa | |||

net weight | 1600kg | |||

Voltage | 220V,3P.60hz | |||

Pre-sale services:

1) Provide the free consultation of the equipment

2) Provide the standard device and the flow chart

3) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

4) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

1. Do you offer installation?

Our machines are almost assembled before loading in container. It is very easy for installation in your workshop. Video guidance and English manual can be provided freely. Engineers can be sent to service in site if the buyer request. all cost in buyer’s account (the machine quotation does not include this cost), including all transportation cost between China and buyer factory (two way), visa and Insurance cost, hotel and eating in buyer country is responsible by buyer, extra labor salary USD200/day.

2. Where can we get replacement parts?

Most of the spare parts are ready in stock. They will be sent to the buyer directly from our warehouse with original prices.

3. How long can we get replacement parts?

Common spare parts can be delivered by express within one week. Some parts can be purchased locally.

4. What technical support do you offer?

1) Technical support by phone, email or WhatsApp/Skype around the clock.

2) Friendly English version manual and operation video.

3) Engineer available to service machinery overseas.

5. Can you customized the machine?

Our machines can be customized made according to buyers’ request.

6. What other machine do you offer?

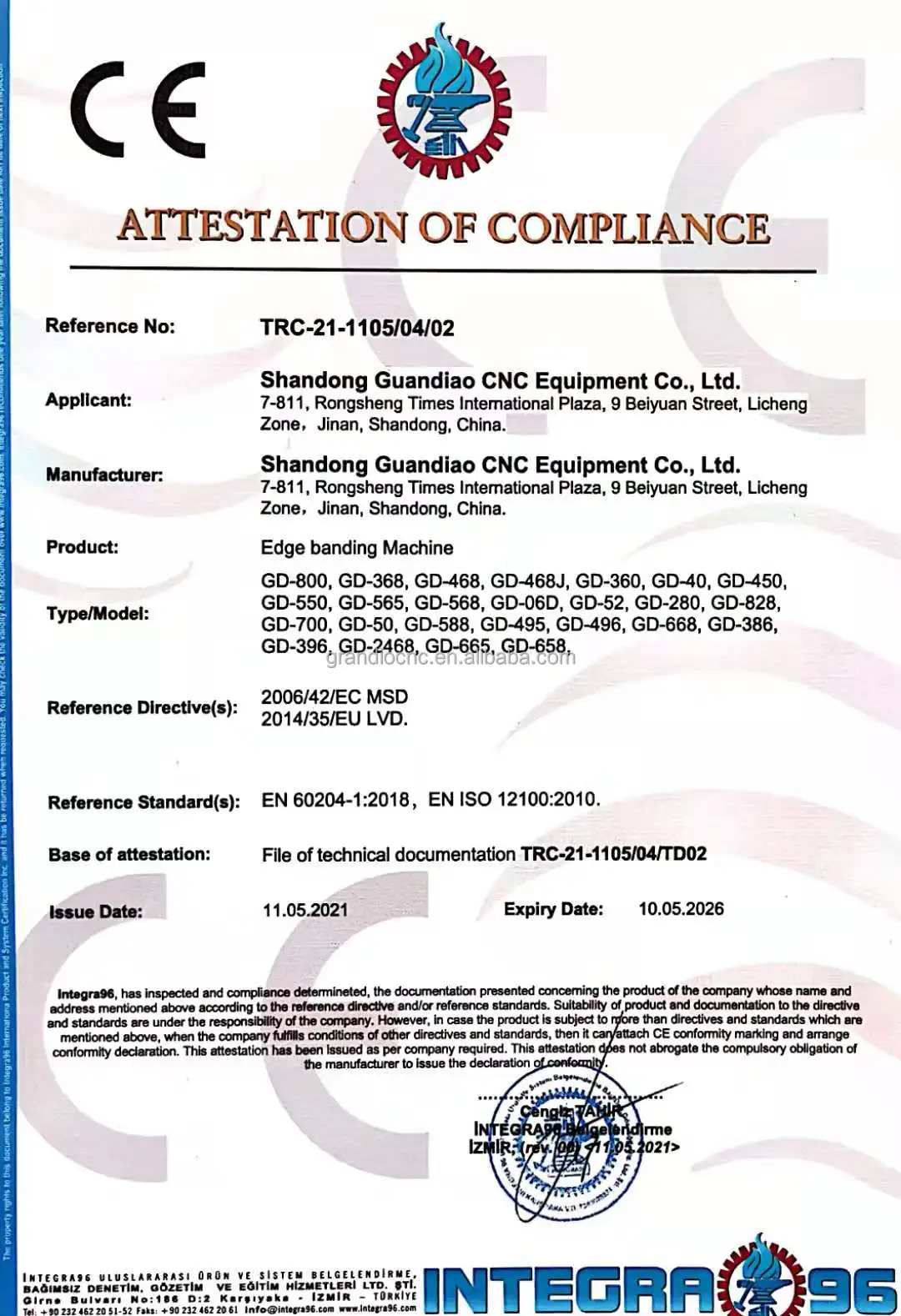

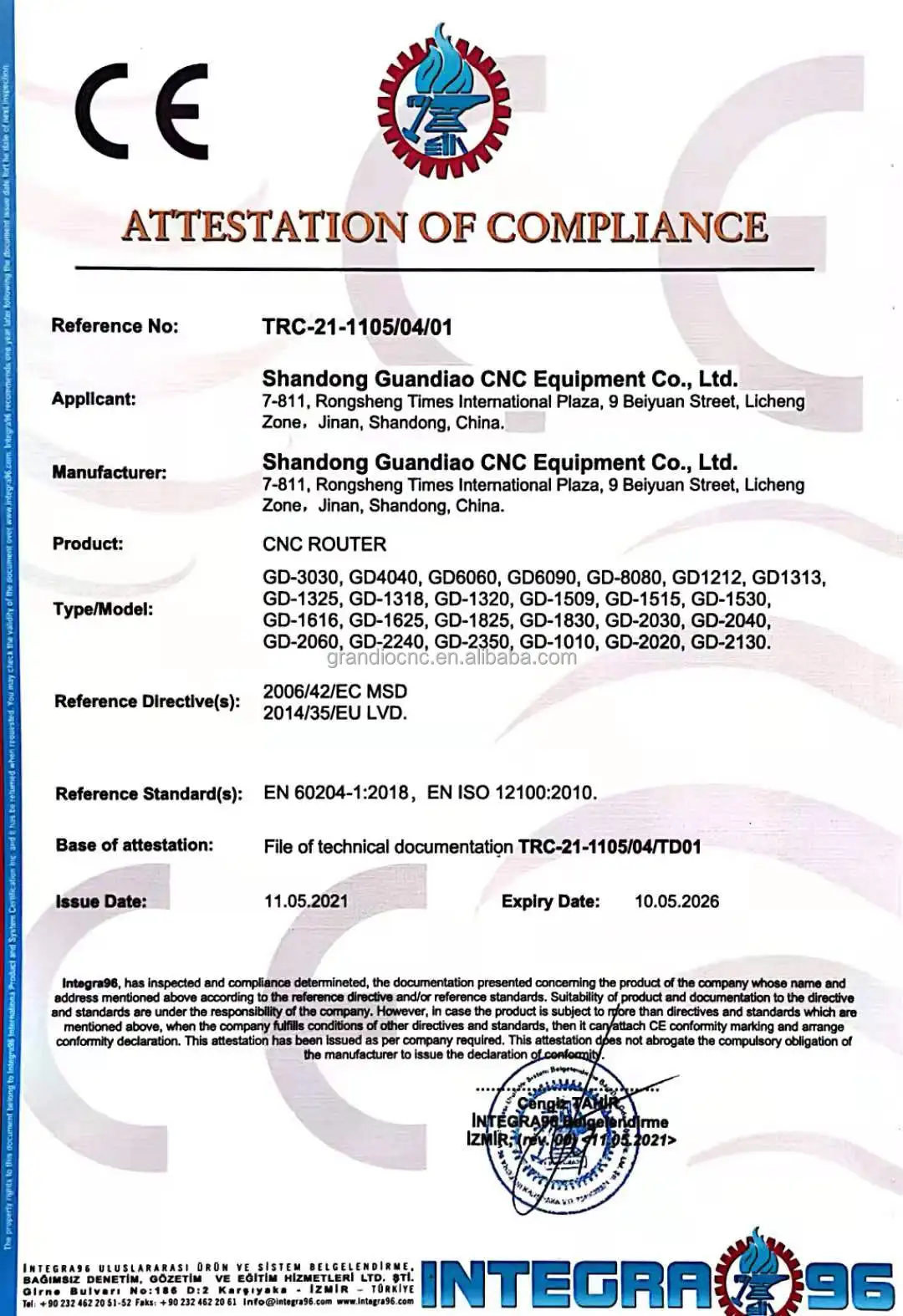

We provide one-stop shop service of woodworking machines for the buyers. Other kinds of woodworking machines, like edge banding machine, CNC router, drilling machine, saw machine,roller coater, spraying machine, membrane press can be provided as well.

7. Can you set the system to our language?

Our system supports common languages like Chinese, English, Russian.etc.

Hot Tags: woodworking panel polishing sanding machine, China, suppliers, manufacturers, factory, price, wholesale, for sale, Brush Polish Machine, Polish Machine, Sander Polisher Machine, Wood Polish Machine, Wood Floor Buffing Machine, Furniture Polishing Machine